This post has already been read 10959 times!

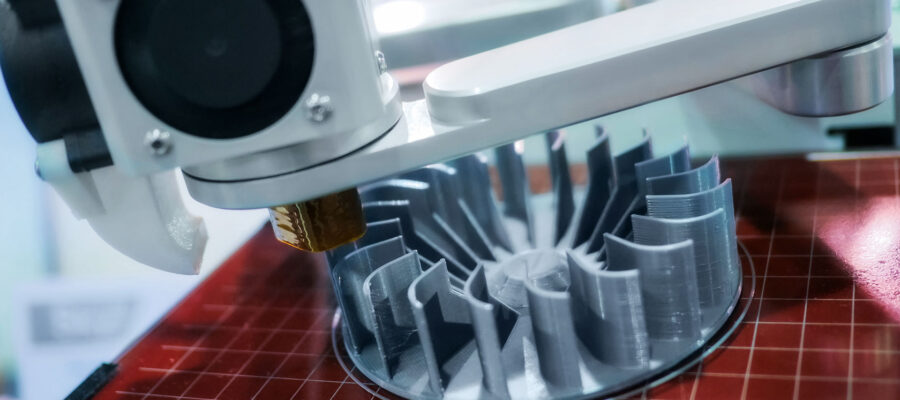

The widespread adoption of 3D printing, a type of additive manufacturing, may soon have a significant impact on the economy.

The global 3D printing market is currently worth around $12.6 billion and is projected to grow at a compounded annual rate of 17% by 2023. As the technology makes inroads into related fields like manufacturing and warehousing, 3D printing is likely to have major supply chain benefits — both directly and indirectly.

The Current State of 3D Printing in Industry

3D printing is most useful in certain situations, like rapid prototyping, small-batch manufacturing and the creation of personalized items, like patient-specific implants. The technology can also be effective for manufacturing jobs with fast turnaround times — or, in some cases, enable a just-in-time approach.

The growing availability of new 3D printing materials has also enabled the quick manufacture of objects from various materials, from plastics to wood, metal and nylon. This makes it a better replacement for conventional manufacturing.

While the initial investment needed for a 3D printer can sometimes be high, manufacturing items with 3D printers is typically cheaper than with conventional methods at small scales. Exact savings vary but can be significant. In one example, researchers reduced the cost of manufacturing anatomical models by $3,720 per case by accelerating the manufacturing process.

"Manufacturing items with 3D printers is typically cheaper than with conventional methods at small scales." – Emily Newton @ReadRevMag Share on XThese benefits — and falling prices of 3D printers — could significantly decentralize manufacturing in the near future and enable greater personalization. This could create new opportunities for the logistics industry and possibly require companies to adapt quickly.

3D Printing Brings New Possibilities for Manufacturers

One of the most significant shifts could be the greater accessibility of personalization and on-demand manufacturing. These two approaches are less practical with conventional techniques, as they need to be retooled to produce individualized items.

With 3D printing, the same machine and operating parameters can be used to manufacture several slightly different items as needed. Manufactured goods could be personalized with unique combinations of features and design specifications as required by a customer.

Some direct-to-consumer startups are already putting this idea into practice and manufacturing items like custom prosthetics for patients.

Industry observers have speculated that the approach may be useful for automotive companies that no longer produce certain spare or replacement parts for legacy vehicles. With 3D printing, these parts could be printed economically and as needed, ensuring they remain available to consumers.

"A great use case for 3D printing, are automotive parts for legacy vehicles. 3D printing makes small on-demand manufacturing practical and economical." – Emily Newton @ReadRevMag Share on XRapid prototyping could also become easier with 3D printing. Because 3D printing requires less lead time on new manufacturing jobs, it’s possible to quickly iterate on experimental or prototype designs with an in-house printer.

Certain goods will still need to be manufactured with conventional manufacturing methods. For example, CNC machining will be more useful to manufacturers who require high levels of precision and minimal tooling of fabricated goods.

However, for many parts where high levels of precision aren’t required and where finishing and tooling after the printing process is a possibility, 3D printing is a very practical and attractive option.

3D Printing and the Decentralization of Manufacturing

3D printers could also help simplify product and raw material sourcing. Currently, many specialized items require advanced facilities to manufacture. Certain ones may also require components that cannot be manufactured at the same site — requiring them to be produced outside a facility and shipped in before the manufacturing process can be completed.

Businesses that need these types of items often have to source them from across the country or overseas, increasing logistics costs and the time to acquire materials and parts. 3D printers can sometimes lower the barrier to entry for manufacturers, allowing smaller companies to fabricate these items economically.

Recommended: How OEMs, Contract Manufacturers and Suppliers Can

Work Together to Optimize a Multi-Tier Supply Chain

The materials that 3D printers use may also have an impact. Compared to conventional materials, 3D printing filaments are highly generic. They can be used to create any product made of the desired material, so long as the manufacturer has enough of the filament.

This could also help simplify manufacturing sourcing and may significantly impact some inventory management practices. For example, just-in-time inventory may not provide much utility if inputs are mostly interchangeable and manufacturers are closer to consumers.

It’s unlikely that 3D printing will be able to fully replace conventional manufacturing techniques. However, the benefits it offers could result in the greater decentralization of manufacturing in the near future. Some businesses may experiment with approaches like point-of-sale manufacturing, where products are fabricated in stores and on-demand.

At the same time, the new possibilities of just-in-time manufacturing may reduce the need for storage of certain goods. This frees inventory space for items that can’t be manufactured with 3D printing.

Overall, this process of decentralization could help businesses rationalize inventory and logistics, reducing the volume of materials and products that need to be moved globally. Shipping volumes and air cargo could be reduced as a result.

The use of 3D printing in manufacturing in supply chains could also help make the supply chain greener. 3D printing is less wasteful than conventional manufacturing and can enable the creation of lighter-weight designs.

3D Printing’s Impact on the Supply Chain

3D printing is likely to have a major impact on the manufacturing sector and the supply chain as a result.

Manufacturing techniques enabled by 3D printing, like on-demand manufacturing, rapid prototyping, and personalized manufacturing, could change consumers’ expectations and alter shipping needs.

"Consumer expectations will likely shift yet again, as 3D printing makes rapid on-demand, personalized products a reality." – Emily Newton @ReadRevMag Share on XAt the same time, 3D printing could help decentralize manufacturing. Interchangeable filaments and lower barriers to entry may make manufacturing near customers more practical.

Logistics companies could also benefit from the rise of cheaper 3D printing technology by offering printing services directly to consumers. This is the approach UPS has taken — outfitting certain stores with 3D printers to provide on-demand services for manufacturers and consumers.

UPS plans to use these early investments to lay the groundwork for a network of on-demand print shops, bringing manufacturing capacity closer to consumers.

In the near future, logistics companies like UPS may help to decentralize manufacturing themselves, opening up new possibilities for consumers and businesses in need of services. There’s little doubt that 3D printing will have an impact on supply chains. These are just some of the likely effects, but the possibilities are virtually endless.

You might also like…

Recommended Posts

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

- Optimizing Inventory and Logistics for Luxury Retail

- Modernizing Defense Supply Chains

- 6 Ways Technology Makes the Supply Chain More Efficient - October 25, 2023

- How Digitization is Enhancing Supplier Relationship Management - May 9, 2023

- A Guide to choosing the Best Pallet Wrapping For Your Needs - November 28, 2022