This post has already been read 12729 times!

Supply chain control towers have risen in response to a very real problem and an urgent need. How well are control towers meeting that need?

Why the interest in supply chain control towers?

One reason control towers are popular is that in an effort to control costs, companies are sourcing supplies and manufacturing from around the world. This specialization and competition has been a good thing, and reduced the cost of goods dramatically. However it has stretched supply chains and introduced new problems, such as increased risk, longer logistics lead time and multiple modes, and dealing with import and export regulations.

At the same time, supply chains are not only longer, they’re more complex, with more companies involved in the production, distribution and selling of products.

All this has to be managed and coordinated. This is a huge problem given that most companies run operations on different systems. Consequently, data is isolated in corporate “silos,” and duplicated and distributed across organizations in the supply chain. As a result data is often difficult to access and share, and when it is shared, it is usually stale.

Can the very technology that contributed to fragmented supply chains, actually solve the problem? Share on XControl Towers: Piecing Together the Extended Supply Chain

The hope is that they will patch together the disparate parties in the supply chain. What is a control tower? Capgemini provides a definition:

The hope is that they will patch together the disparate parties in the supply chain. What is a control tower? Capgemini provides a definition:

A supply chain control tower is a central hub with the required technology, organization, and processes to capture and use supply chain data to provide enhanced visibility for short and long term decision making that is aligned with strategic objectives.

– Capgemini Consulting, “Global Supply Chain Control Towers”

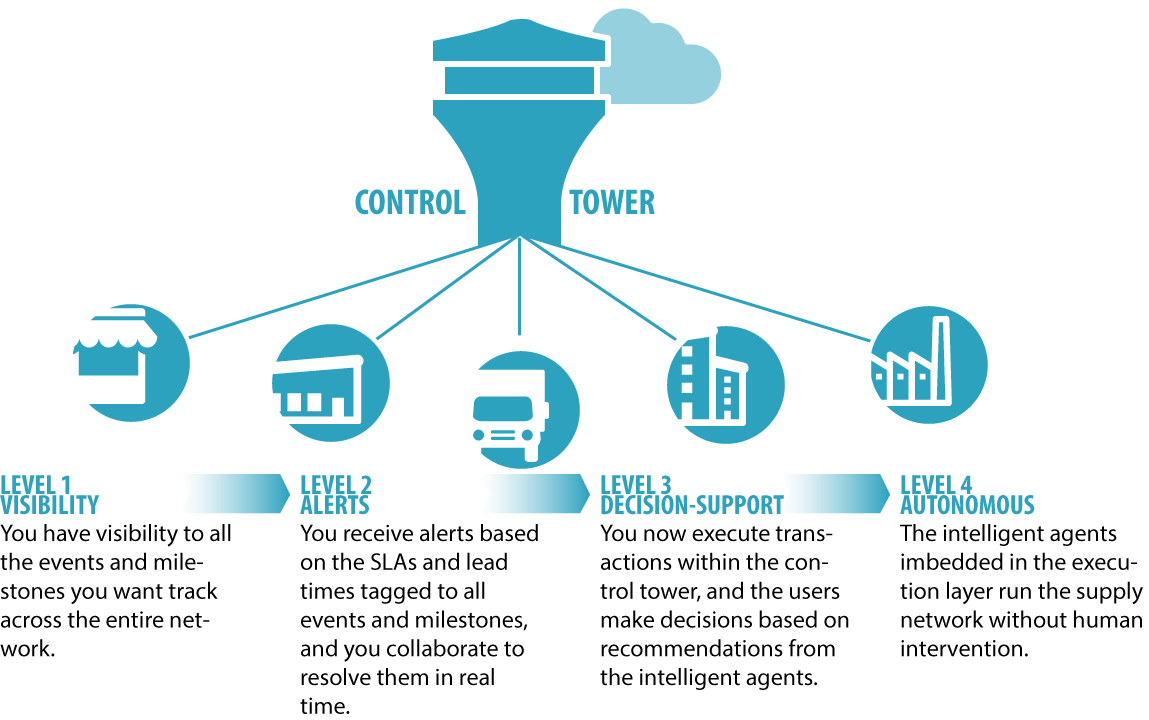

We can call this Control Tower 1.0 and it provides valuable but limited functionality. It gives visibility to conditions and alerts across the entire supply chain and serves as a single console for overseeing and managing the supply chain.

Control towers have evolved rapidly, and in recent years have come to include alerts and decision-support capability. We can call this Control Tower 2.0. The goal is to make control towers more than mere onlookers but to provide data and tools, such as predictive and prescriptive analytics, that can help supply chain managers respond to shifts in demand and supply more effectively.

This evolution to Control Tower 2.0 is a big improvement, offering visibility across the extended supply chain, and analytics to help cope with issues as they arise.

However, there are still problems.

Problems with Control Towers

Although Control Tower 2.0 does help to piece together the puzzle of the global supply chain, it does have its flaws:

There is limited operational scalability across enterprises

- Connectivity and integration – different technologies for connections and different applications, often resulting in unique apps built on unique connections

- It involves a cumbersome onboarding process

- Heavy emphasis on human interaction with planners responding to alerts

Trading partner connections are point-to-point

- Control towers use hub and spoke model and cannot reuse these connections

- Use of different technologies for each connection and sometimes different (ad hoc) applications – meaning you often have unique applications built on top of unique connections

Decision support is weak

- Aggregate reporting of stale information with exception alerts

- Labor intensive – human planners must manually evaluate alerts and determine the best response to correct the issue

- Slow – due to its manual nature corrective action can take a long time

Visibility-centric with disconnected and uncoordinated planning and execution systems

- Enterprises still have separate systems for planning, execution and business intelligence

- Plans may be manually adjusted faster, but execution is still slow

- The result is that response is slow and can take weeks

Many of these problems stem from the underlying technology. Most control tower solutions are built on enterprise-centric technology, the very technology that contributed to the disconnected supply chain in the first place.

How can the very technology that contributed to the problem be expected to solve the problem?

Building a Better Control Tower

So how do we build a better control tower? All the problems above have to be addressed. It is possible and it has been done. The latest control towers are built on new technology, leveraging technologies like multiparty networks, machine learning, and autonomous virtual agents. They are delivering some surprising results.

You can learn more about these new intelligent control towers here. They will explain the four stages of control tower maturity and will be taking an in depth look at the evolution, the technology, and the benefits of today’s advanced control towers, and some case studies of companies using control towers and the results they’re seeing.

This will be a lively discussion, so bring questions and get answers. Save your seat now and attend live and get the recording.

References

- Capgemini Consulting, “Global Supply Chain Control Towers” available Capgemini.com

- For an up to date evaluation of control towers available from vendors today, see the Supply Chain Control Towers Value Matrix, Nucleus Research, 2019

- How to Avoid a Technology Horror Story - October 31, 2024

- How Chain of Custody Strengthens the Supply Chain - October 11, 2022

- Inside Next Generation Supply Chains - November 8, 2021