This post has already been read 41286 times!

How robotics are improving packaging, supply chains, and impacting customer experience and expectations

Robotics have penetrated into the supply chain significantly, particularly into warehouses, but less so in end-of-line and packaging. While end-of-line automation has existed for years, recent technological developments have permanently transformed it. Intelligent, autonomous and specialized robotics have become practical, cost-effective solutions. How will they influence packaging systems? What are the broader implications of their integration into the supply chain? Let’s dive in!

How Robots Fit Into Advanced Packaging Systems

Labor scarcity has been among the main drivers for automation advancement for years. To date, it is still becoming increasingly difficult to fill open positions and retain new hires. In the past, workers would stay in their role for decades — maybe even for the entire duration of their careers. Now, industry experts say they remain for around three years before moving on.

With no end to the widespread workforce shortage in sight, automation solutions like robotics offer significant advantages beyond replacing human labor. Is is also no longer simply a matter of competitive gain — the adoption of automation is frequently tied to growth. While there is a tendency for companies to lower standards and expand their hiring pool to fill roles, companies that invest in digitalization, automation, and robotics, stand to benefit in the long run.

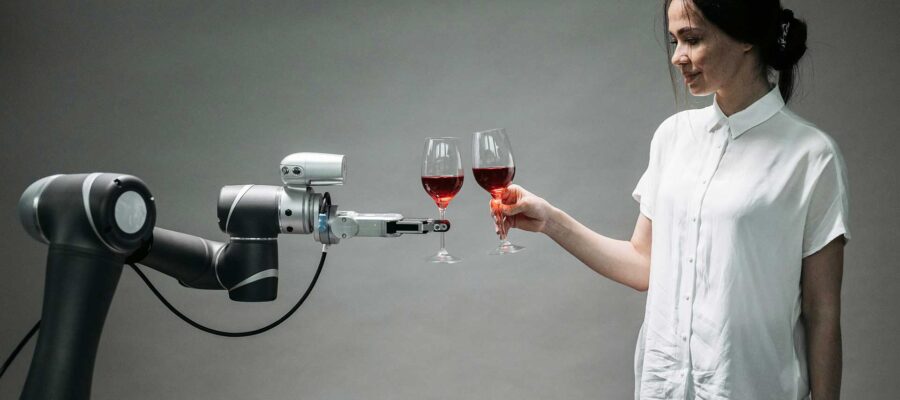

The role of robotics in advanced packaging systems and how they are impacting supply chains and customer expectations… Share on XIn addition to supplementing the workforce, robotics solutions prevent downstream delays by improving workplace safety and boosting productivity. These machines can work alongside humans or independently, streamlining packaging in any facility. They are becoming more capable, as they leverage machine learning, the cloud, and the Internet of Things (IoT), often making them able to fill fairly skilled positions.

Whether management opts for articulated manipulators or collaborative robots — cobots — they enhance their end-of-line processes. These machines don’t require breaks or time off. Facilities are more resilient to surges in customer demand, help to ensure consistent quality, and can compensate for upstream delays.

Applications of Packaging Robots in Various Industries

Robotics markets are massive in most industrial sectors because they address long-standing supply chain pain points. For instance, in pharmaceutical packaging, regulatory compliance is critical. While facilities must maintain precision and consistency, speed is essential for meeting consumer demand — which, in many cases, is a life-and-death situation.

With turnkey loading robots, factories can load pharmaceutical products quickly and precisely. For example, after one machine uses a vacuum attachment to grab up to 40 pre-labeled vials simultaneously, another places the required amount into partitioned cartons. Pressure sensors enable the robots to handle delicate pipettes. Similar systems can accurately dispense medication.

In food and beverage production, cleaning is crucial to regulatory compliance. If a facility doesn’t meet food safety and quality standards, people can become ill — causing the entire supply chain to grind to a halt as regulators investigate. Sanitary wash-down robots are hygienically designed to meet Food and Drug Administration standards. They can withstand the rigors of harsh cleaning agents and frequent sanitation procedures without incurring damage.

Experts estimate the market size for food robotics will reach $8.9 billion by 2033, up from $3 billion in 2023, achieving a compound annual growth rate of 11.5% during the forecast period. While 88% of leaders intend to integrate robotics in the near-term, it is estimated that there are already about 3 million robots in operation around the world.

Experts estimate the market size for food robotics will reach $8.9 billion by 2033.

Market.us

In consumer electronics, robots can form cartons, position partitions, load products, arrange package inserts and place labels. As the trend to miniaturization accelerates, precision will be vital, in order to handle and place smaller parts amidst growing complexity. Articulated manipulators must place products carefully and precisely, in order to safeguard against damage in transit. Failure to do so, will result in disgruntled customers and will trigger returns and reverse logistics.

Selective Compliance Articulated Robot Arms are ideal for applications like these. These machines can handle lightweight parts using lateral movements. While their reach is limited, they form and follow patterns with precision. Their ideal applications include assembly, kitting, packaging and palletizing.

The Effects of Robotics Integration on Supply Chains

Advanced packaging systems benefit from robotics, by enhancing productivity, efficiency, and increasing or maintaining quality. These gains translate to increased customer satisfaction and improved brand reputation. Benefits like these are why McKinsey estimates automated systems will make up 25% of capital spending in the next few years.

Industry giants are adopting robotics and demonstrating the advantages. instance, one of Amazon’s top-performing packaging solutions is an intelligent robotic arm named Sparrow. Unlike traditional models, it does not struggle with variable weight, texture, shape or malleability. It can handle approximately 65% of Amazon’s inventory, which contains 100 million products.

Solutions like Sparrow come close to matching in humans, with delicate “fine motor skills” and “judgement.” This helps streamline the shipping process while preserving product integrity. They can even reduce resource usage by creating custom packaging, thereby reducing waste.

Technological breakthroughs like machine vision and remote sensing will continue to drive the evolution and increasing sophistication of packaging systems. Strategically timed investments will help management capture the benefits of robotics integration while providing flexibility for upgrades.

Packaging Robotics Will Impact Supply Chains and Drive Customer Expectations Higher

As more organizations incorporate robotics into packaging systems, supply chains will benefit and evolve. Packaging can have an impressive impact on customer experience, just consider the experience of opening a product from Apple. Well-designed and packed products enhance the customer’s experience, but robotic high precision and custom packaging also impact the supply chain in less obvious ways.

We can expect to see shorter cycle times from steadily increasing productivity, quality, and output during end-of-line processes. This, in turn, will accelerate downstream operations like distribution and last-mile delivery. Robotic systems should also help minimize damage to products, especially while in transit, reducing the need for reverse logistics.

With robot-driven automation, supply chain leaders can save time and increase their resiliency to unexpected disruptions. Eventually, these gains are likely to influence consumers’ shipping estimate expectations, ultimately leading to more widespread same-day shipping as an option.

The role of robotics in advanced packaging systems and how they are impacting supply chains and customer expectations… Share on X- How to Use Predictive Analytics to Streamline Cross-Border Logistics - May 19, 2025

- The Role of Robotics in Advanced Packaging Systems - December 4, 2024

- Ensuring Supply Chain Resilience Through Enhanced Visibility - September 24, 2024