This post has already been read 12435 times!

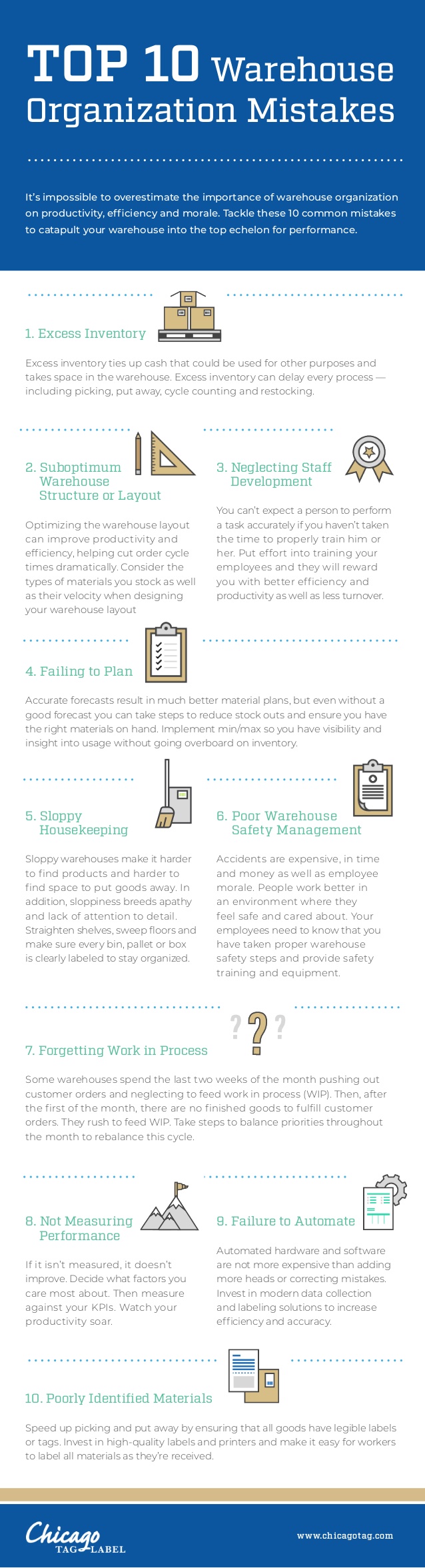

Inventory may not be all you’re stocking in your warehouse. If you’re not careful, your mistakes could be piling up and creating a dangerously inefficient situation. In particular, the errors you make by failing to organize your site properly can be exceptionally costly. Sloppy warehousing procedures can be a significant drain on your productivity, efficiency and even employee morale. You can’t expect the best performance from your warehouse operation without being alert to these common missteps and tackling them head-on when they occur.

For instance, one of the worst blunders any manager can make is neglecting the development and training of staff. It’s nearly impossible for any industrial workplace to function as well as it should when employees aren’t sure what’s expected of them. Another common issue is a lack of cleanliness and order, which can create serious disruptions. Taking time to keep shelves neat and organized should be a top priority for every manager. Of course, safety also needs to be top of mind, as accidents can be expensive in more ways than one.

To make sure you’re not stockpiling hazards along with your products and components, take a look at the accompanying infographic. It details many of the most frequent mistakes made in the supply chain and why they are so dangerous.

Recommended Reading

- Modernizing Defense Supply Chains - January 11, 2025

- Supply Chain Crossword Challenge - October 30, 2024

- Infographic: 6 Requirements for Transforming Supply Chains with Artificial Intelligence - June 10, 2024