This post has already been read 14782 times!

Synchronization. It’s by far the most overused term in the supply chain lexicon. For some reason, everybody wants their supply chains to be “synchronized”.

Synchronization. It’s by far the most overused term in the supply chain lexicon. For some reason, everybody wants their supply chains to be “synchronized”.

Taken literally, the expectation seems to be that all supply chain activity should happen at the same time. This explains why so many retailers seem to be gung-ho about sharing “up-to- the-minute” POS and inventory data with upstream supply chain partners.

The problem with this thinking is that it tries to circumvent the natural order of things in the supply chain. Products that are being sold from store shelves today were shipped a couple of days ago, put into stock at a distribution centre a couple of weeks ago and

manufactured a couple of months ago. So much for synchronization.

Until we can find a way to manufacture, distribute, ship and merchandise inventory all just moments before it is demanded at the store shelf, we must accept the fact that true

synchronization is not economically achievable for most supply chains.

So if trying to achieve synchronization is the business equivalent of banging one’s head

against a brick wall, then what can be done to make the retail supply chain more responsive?

The answer may lie in the second most overused supply chain term: integration. From our experience, it seems that many companies today interpret the word integration (and, for that matter, synchronization) as meaning “to send a lot of information all over the place”.

Recent attempts at achieving integration in the supply chain are a lot like aerobatic flying teams. Every maneuver requires a series of steps to be performed in sequence and information is being shared among the pilots in the form of radio signals. Through years of planning and practice, it may look as though they are integrated, but in the end, it falls to each individual pilot to interpret what’s going on from their own unique vantage point. If something unplanned occurs with one aircraft, there’s no automatic adjustment that happens in the other nine to compensate. As exciting as this is, it’s also very dangerous.

In many ways, information sharing strategies like CPFR are like this. Information is shared and guidelines are adopted, but in the end it requires a great deal of effort and requires a number of different parties to make the same interpretation of events to be successful.

Supply chains should be boring. Unexpected things may happen, but the consequences of them should be as easy to predict as tomorrow’s sunrise. When your supply chain is boring, then you know that you’ve achieved true integration

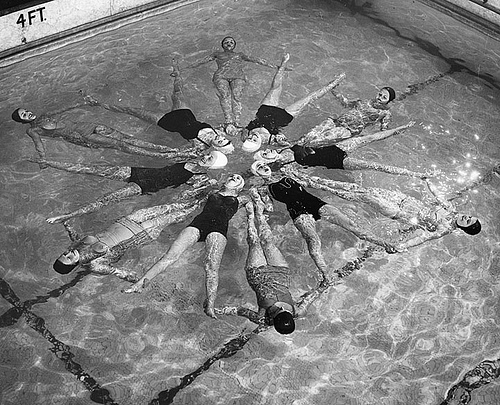

Forget all the metaphors that try to make supply chain planning sound glamorous and exciting – a rowing team working in harmony, synchronized swimmers in a flawless performance or aerobatic squads colouring the sky. A properly run supply chain should be like a good ol’ reliable (and boring) freight train.

The consumers represent the engine of the train and the manufacturing plant is the caboose, with the rest of the cars being everyone else – distributors, transportation

providers, retail stores, etc.

When the engine speeds up or slows down, you don’t have to check with every car to make sure that they’ve received the message. Once the cars have been connected in sequence, the integration is built in by design. Once you know what the engine will do, then the caboose’s actions are predetermined and predictable.

So how can you make your supply chain boring? A new way of running a retail business is emerging and it allows full connectivity (speaking of overused terms) from the shelves of the retail store right back to the factory.

It’s called Flowcasting.

Related Posts

Why connecting an entire supply chain to a network platform makes sense….

The recipe for supply chain success for nearly every industry

Photo Credit: uwdigitalcollections

- Small Data, Big Insights - July 14, 2016

- Is Flowcasting the Supply Chain Only for the Few? - June 3, 2016

- Philosophy - February 12, 2016