This post has already been read 11667 times!

How to manage and optimize a direct-to-consumer supply chain.

In the Consumer-Direct Strategy Part 1 post, I discussed why having a direct-to-consumer strategy was more important than ever. Now I’d like to talk about building and executing an effective direct-to-consumer supply chain.

Achieve Economies of Scale with Single Item Demand? Really?

Process automation has, of course, been available for many years in pockets across the supply network. Today that automation has been extended across the network and into the home with the ability to trigger a response from the network, based on individual home-based orders. In essence we have now enabled one-step home delivery powered by a supply network ecosystem that meets the demand of the individual in real time across the last mile, while also aggregating this demand in real time across all customers to leverage economies of scale.

This allows the network to achieve the highest levels of customer service at the lowest possible cost, even when the orders are home-based for individual items.

“The upshot is that no one knows what will happen in the next 3, 6, or 12 months, so a new approach is needed: End-to-end visibility with an autonomous supply chain that combines planning and execution in real time.” -Joe Bellini @onenetwork

In fact, because One Network’s NEO Platform is a true multiparty transactional software network, the overall data model is designed to be bottom up, starting with the unit level single item and building up from there. So the platform works across all levels of aggregation, whether you are planning six months out or executing a delivery this morning. Thus, as the market shifted over the past few months due to the pandemic, to one driven by consumer-based single item demand at the home, the network already had both the data infrastructure and the software functionality to enable the shift in real time.

Recommended: The Consumer-Direct Strategy for Manufacturers and Shippers

This is similar to the shift discussed earlier in the restaurant industry, although opposite in direction, as the network needed to rapidly slow down rather than speed up. In the restaurant example, all demand was driven by items ordered off the menu and served on a plate, resulting in similar dynamics for single item demand across a multi-tier supply network.

Making Optimal Supply Chain Decisions Network-Wide

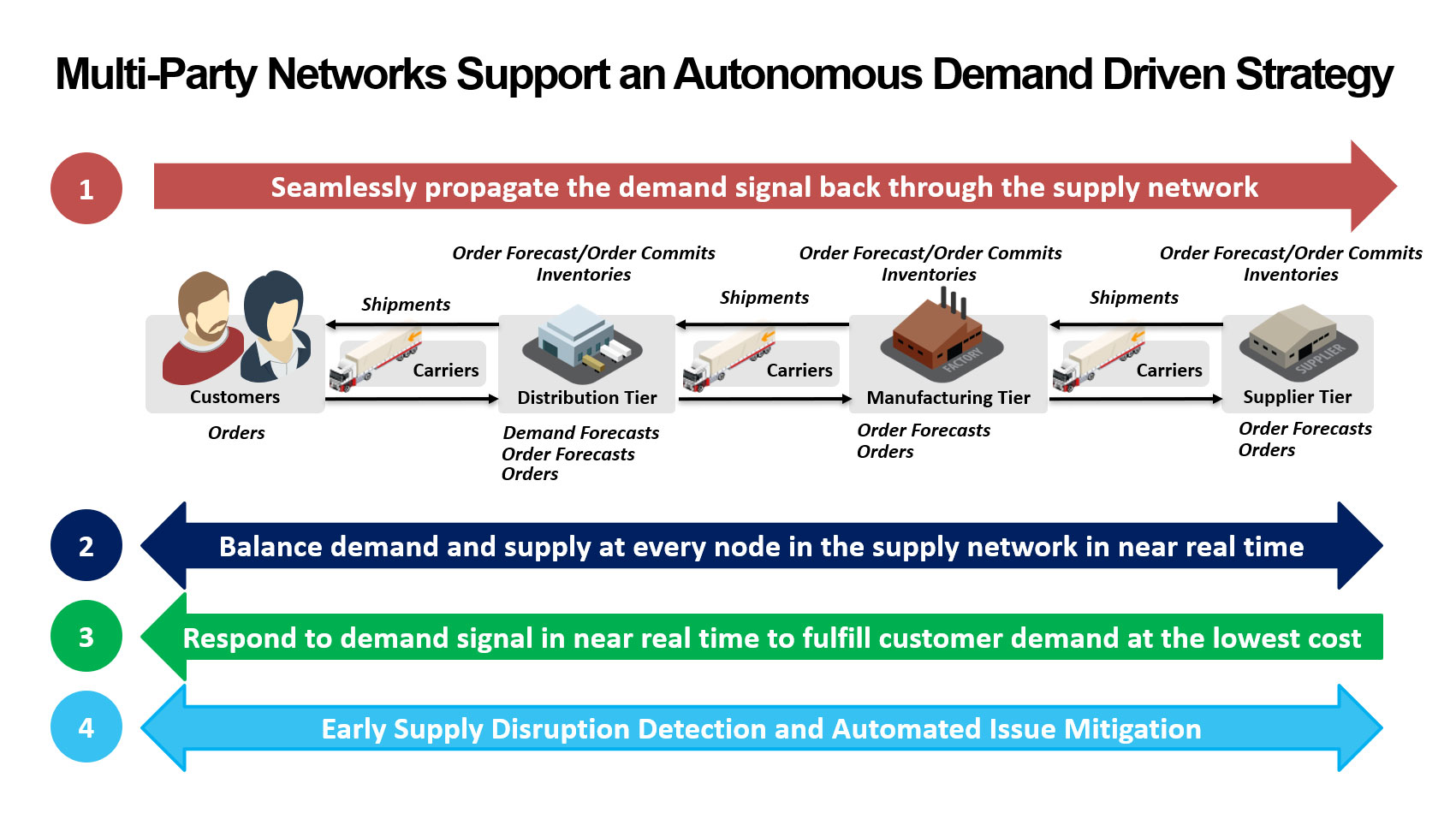

The nature of the network is to view inbound and outbound orders as two sides of the same coin. What one trading partner considers inbound another considers outbound. Thus, the only way a last mile solution can benefit both the consumer as well as the companies providing the goods and services, is to optimize all inbound and outbound across the network. Providing visibility, control, and math-based decision-making at different supply chain touch points empowers trading partners to make well-informed decisions about positioning and moving inventory.

The only way a last mile solution can benefit both the consumer as well as the companies providing the goods and services, is to optimize all inbound and outbound across the network. -Joe Bellini @onenetwork Share on XGiven the number of variables in play across a complex network, you will be relieved to find that automated and math-based workbenches to aid in decision making are available today. In the shift toward becoming more demand-driven, companies need to weigh various options such as Incoterms selection based on geography in order to drive carrier preferences, transportation pricing, and inventory ownership.

Another tactic is to divert inbound product at ports of entry to match real-time demand shifts and related mode selection. Companies have the option to segment parts, sort by mode, prioritize by need, then pair components at a fulfillment location closer to demand. This approach enables you to be highly responsiveness but at a lower cost, while also reducing the carbon footprint.

This is real time knowledge across the network, along with the ability to collaborate between trading partners, drives better performance for all participants.

Participating in these business networks also gives you significant opportunity to expand your customer base. Capabilities like telematics and full order visibility empower customers and drive up satisfaction levels, which in turn drive word of mouth referrals. For companies that measure NPS (net promoter scores), these capabilities are certainly a strong accelerator in driving customer loyalty for the direct-to-consumer channel.

Planning Without Execution is a Fallacy

In today’s world, the idea that planning is enough, even with what some are calling rapid response planning, is ridiculous. The pandemic has taught us some hard lessons in regard to planning.

- Scenario planning has become pointless in today’s climate. No one knows what the future will look like, so there is no point creating complex planning scenarios. After all, how many plans factored in today’s scenario? It’s one nobody could have predicted.

- Traditional forecasting is not going to give an accurate forecast. It’s impossible to forecast consumer behavior based on the past, and the lockdowns are different country- by-country and state-by-state with rules changing rapidly over time. As we’ve said, the shift to ecommerce sales has been dramatic and could not have been forecast.

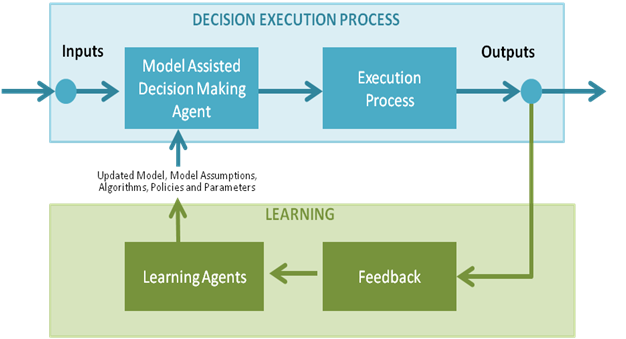

- The future is uncertain. No one knows what will happen in the next 3, 6, or 12 months, so a new approach in supply chain management is needed. We need end-to-end visibility with an autonomous supply chain that combines planning and execution in real time.

Remember that the closer you are to making delivery, the more your decision-making is compressed. Within the delivery window you are executing transactions, not planning. If a network platform does not provide seamless planning and execution across all phases of forecast, commit, and delivery, then it is not capable of enabling demand-driven logistics. Without this seamless environment across time horizons, the risks of failure are significant because you have less time to react and fewer choices when taking action.

If a network platform does not provide seamless planning and execution across all phases of forecast, commit, and delivery, then it is not capable of enabling demand-driven logistics. -Joe Bellini @onenetwork Share on XCoordinated planning and execution control is critical to logistics performance whether it’s cross-docking to expedite retail replenishment and avoid stockouts, or dynamically routing last-mile shipments to meet delivery demands. Demand-driven capabilities like postponement must be woven throughout the supply network.

In fact, in order to be demand responsive in real time, a single cloud-based platform which includes procurement, contracting, shipment planning/execution/tracking, yard management, appointment scheduling, and financial/claims settlement must be included in the multi-party planning and execution services available on the network.

For enterprises saddled with technology silos and separate systems in these functional areas, achieving real-time responsiveness is simply unattainable.

The Demand Driven Manufacturer

From the shipper’s perspective there are many variables where you feel that you have little or no control – such as consumer buying patterns, fuel costs, supply disruptions, and capacity allocations. You can try to apply statistical forecasting techniques or even machine learning but these variables will always be difficult to predict. Regardless of how low you can drive forecast error, you will always need to react to problems and alerts during execution, and basically be in “reactive mode.”

Deploying the demand driven logistics capabilities we’ve discussed, will empower manufacturers to drive collaboration across their trading partner ecosystem including customers, carriers, and suppliers, leading to improved costs and customer service levels. Transportation management systems (TMS) and real time supply network capabilities around visibility, decision making, orders, inventory, and fulfillment all available on a single cloud-based platform provides shippers with the ability to share information and manage transportation and logistics processes throughout the network. Having data in one federated master data management (MDM) repository that feeds upstream planning and analysis helps facilitate demand-driven logistics.

Making “Order Size One” Work

We must also remember that the dominant philosophies upstream in the supply network have been to enforce minimum order quantities in order to drive efficiencies and lower costs. Today shippers must process a “little-and-often” approach that is predicated on point-of-origin collaboration and consolidation to move smaller quantities more frequently based on real time demand updates.

On the surface this approach appears like it may push additional costs onto the manufacturer, but that does not need to be the outcome.

In fact, it is possible to move to smaller order quantities and actually decrease costs as long as the real time network visibility and collaboration reduce variability for all trading partners and eliminate information lead times from a demand perspective across all tiers and echelons.

Sub-optimizing each tier in the supply network, separating tiers with large inventory buffers, and the “toss it over the wall” mentality that creates the bullwhip effect upstream in the supply network, must all be eliminated to enable the ordering of smaller quantities from suppliers while keeping costs the same or even lowering them. Once all trading partners have visibility to the big picture – which is that no one really gets paid until the end customer buys a product or service – then the trading ecosystem can really thrive. Then, from a transportation perspective, mixed loads will become the new normal.

It’s Still an Omnichannel World

Even as a growing fraction of your business shifts toward direct-to-consumer, you still need to manage multiple channels on a single platform, with integrated logistics management from first mile to last. Fortunately, leading business network platforms handle that seamlessly, with a unified view of demand across all channels, along with the ability to execute, forecast, and plan.

The Value Potential is Huge

Now let’s summarize the opportunity. For manufacturers and suppliers, a demand-driven consumer-direct strategy enables you to take back control of your supply network and capture value in these areas:

- With end-to-end visibility, everyone in the network knows what’s going on in real time – identify and respond to issues more quickly

- Optimize inventory across the entire network with multi-echelon inventory optimization (MEIO) – liberate working capital

- Implement autonomous supply chain management to balance demand and supply, and manage transportation more optimally – drive out cost

- Execute on consumer-direct “drop ship” logistics to increase ecommerce sales and gain market share – maintain revenue growth

On top of all this, strengthening your consumer-direct channel mitigates risk and offers manufacturers a sure way to blunt the impacts of a retail market that may take years to recover.

What’s Needed is a Real-Time Reach Across All Tiers in the Supply Network

For those who are sourcing globally, failing to communicate in real time with upstream partners creates significant inefficiencies and costs. Trying to do so across dozens of deployed ERP instances will be like being tethered to an anchor. Today companies must strive to reach across all tiers in their supply network and work more closely with suppliers and manufacturers to fine-tune production systems and make sure they are in lockstep with downstream processes.

What’s needed goes well beyond a basic ecommerce platform.

What’s needed is a complete supply chain solution with integrated multi-tier inventory optimization, order brokering, merge and cross-docking, including last mile delivery, and the ability to create an allocated Available-to-Promise (ATP) for order promising to a delivery window in a home within a few hours. And all this needs to be optimized on cost.

A tall order? Perhaps not. Today’s network platforms make it possible, and in this way, you’ll enable your whole ecosystem to capitalize on the shift toward direct-to-consumer and achieve a fast ramp in consumer-driven last mile deliveries. And you’ll be fully prepared to capitalize on new opportunities now and as economies recover.

I’ll be diving into the Consumer-Direct Strategy in detail on a webinar. If you’re interested in this topic, you’ll get a lot more out of the webinar as Tom Lee (Lovesac) and I pull back the curtain on exactly how to execute an effective direct-to-consumer strategy. Sign up here:

Recommended: The Consumer-Direct Strategy for Manufacturers and Shippers

- 8 Actionable Supply Chain Trends for 2023 - January 19, 2023

- Constraint-Based Supply Planning & Execution - November 21, 2022

- Supply Chain Planning Control Tower - September 29, 2022