This post has already been read 23530 times!

Is supply chain technology finally poised to meet market expectations?

I don’t know about you, but having spent more than a quarter century in Supply Chain, there is one indisputable law above all else…

Change is coming.

Even in the best of times, variability is the absolute change that constricts the supply chain. In supply chain variability comes in three forms: Demand Variability, Supply Variability, and Lead Time/ Cycle Time.

Impact in any one area will be an impact on all other areas, guaranteed.

The graphs below are from the US Federal Reserve on these topics with the “bullwhip” mapped to show the systemic impacts.

Figure 1: Demand Variability – Advance Retail Demands (FRED 1998-2023)

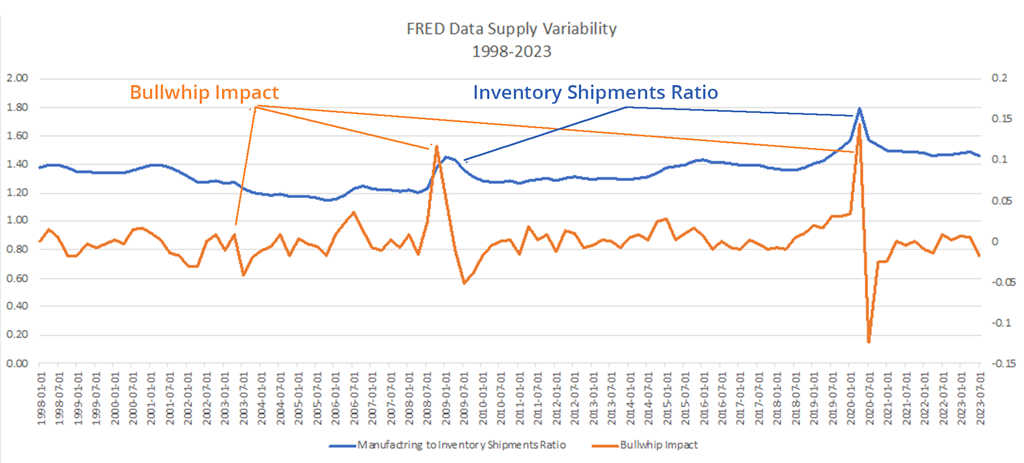

Figure 2: Supply Variability (FRED 1998-2023)

Figure 3: Delivery Lead Time Variability (FRED 1998-2023)

Over the recent past, these three variables have never been more impactful on the global supply chains, nor more evident to the public.

As consumer demand and channels changed no one was ready to embrace these changes as fast as they had in the past. With those demand changes it created a bullwhip effect on supply. With the pent-up demand and supply catching up, all order cycle times, and capacity constraints created longer lead times to get product to the point of consumption.

What is on the Horizon for Supply Chain Management? Five emerging trends shaping the supply chains of the future… Share on XOf course, I am talking about the obvious impact of COVID-19; but in the supply chain we know COVID was just another “thing”. The impacts it caused are not new because of COVID, nor have they fundamentally changed in the past 25 years.

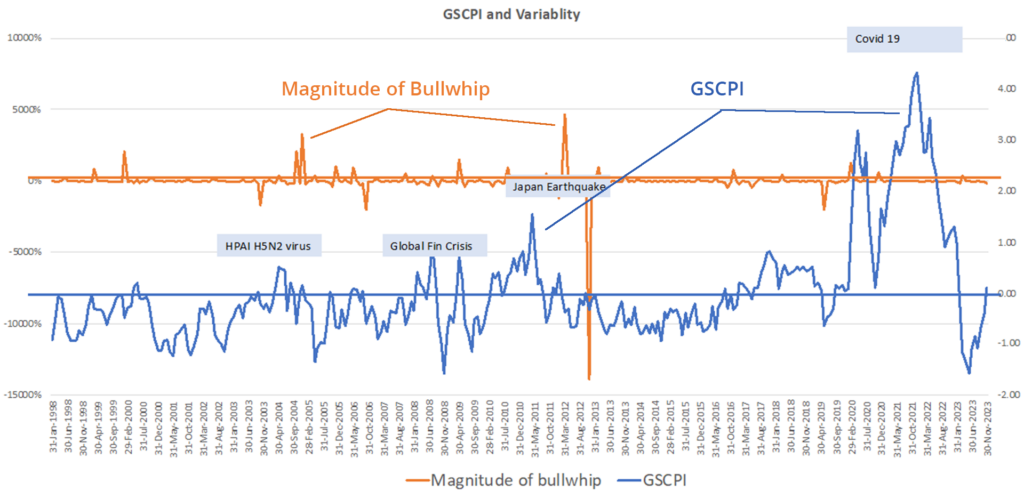

Variability drives disruption in global commerce. The Global Supply Chain Pressure Index (figure 4) is published by the NY Federal Reserve, and it clearly shows that both the amplitude, frequency, and wavelength of risk on the supply chain are all increasing.

Now the bad news, it’s not going to change or get better.

The more data and insights we have access to in this connected world, the more pronounced impacts will show up.

The good news is, that business processes and technology have found their way to an intersection and inflection point that can dampen the amplitude, shorten the wavelength, and reduce the frequency without having to start over.

But the best news is this allows companies to be both agile and resilient at the same time, and in ways that before were just words on a slide.

In this article, we will lay out five trends that are emerging, which enable true agility and resilience for supply chains.

The Data Imperative

W. Edwards Deming said it best, “Without data, you’re just another person with an opinion.”

And when it comes to the supply chain, data is king. Yet it has always been the elusive element that has tripped up many initiatives and digital transformation strategies.

Companies that have figured out how to collect master data, cleanse it for use, and keep it in sync with low effort will dominate. They will be act with confidence, quickly, and far more effectively than their competitors. A fact that should alert us all that quality master data is imperative, is the fact that, in the US alone master data management (clean and manage) is a multi-billion-dollar market.

But supply chains don’t operate on master data alone.

It is the transactional data that moves the needle. Ask anyone in the supply chain and they will inevitably say something like, “Supply chain data is just bad. If I could only get standard clean data, things would be easier.”

Today, with the immense computing power we have at our disposal, the ability to leverage data structures and match both contextual and unstructured data keeping master and transactional data in sync with operations is the minimum viable product; a ground for entry into supply chain management. The market is fiscally and mentally exhausted with investing in point solutions that promise best-of-breed and are only left with another problem of keeping data in sync with other applications.

In future, we will be looking for ways to lower the total cost of operations concerning data and, at the same time, trust that data to be reflective of their operations. Those systems that can embrace and/ or replace other applications because of the value of connected quality data, will deliver more value faster than companies have experienced for decades.

True Supply Chain Visibility (Beyond Tier 1 and Tier 2)

It’s a simple principle; “If you can’t see it, you can’t solve it.” This marketing mantra of supply chain visibility has been top of mind and in every analyst report for decades. Ultimately the goal is right, but the approach is flat-out wrong. For far too long visibility solutions promised the value of visibility and failed at the delivery.

So why isn’t it solved?

There is one reason at the root of all the others. Let’s follow the value. If visibility is sold to any entity in a supply chain but there is no value to the connected partners for sharing their data, then the adoption, use, and consistency will not be sustained.

Supply chains and technology that extend (or propagate) real-time demand, orders, shipments, and alerts to the network of providers will get more assurance of participation, visibility, and value from all their visibility.

Those who continue to adopt visibility in a one-way process of ingesting data for visibility from their partners without direct value back to them in the same platform will never eliminate the blind spots in their supply chain.

“Those who continue to adopt visibility in a one-way process of ingesting data for visibility from their partners without reciprocating value, will never eliminate the blind spots in their supply chain.”

Kent Ledgerwood

Today, companies are looking to stop spending money on partial coverage, supplier negotiations to get data, or spending more to get the bare minimum. Those solutions that have the ways and means to offer visibility and propagation to all parties will see direct benefits and deeper visibility into their supply chain.

ESG & Risk Management

Sustainability, legislation, and geopolitical issues are just a few areas that, are not new factors that impact the supply chain.

While the next environmental, social, governance (ESG) initiative or global risk is not known, companies that can adapt and embrace without significant redesign will win. Not only will they win in operational execution, but they will also be afforded brand recognition for the compliance and difference their brand can show to the consumer.

ESG must cover scopes 1,2 and 3. It’s not enough to look in the review mirror to see how much carbon or climate impact was generated. No, companies need the data at all tiers of their supply chain and decision logic that can provide prescriptive answers on how to optimize in real-time before a decision is made.

When it comes to risk there is no magic wand to know what risk is coming or how long it will manifest its influence. Alerting systems that show the potential impact on a supply chain was a good start but it didn’t go far enough. Risk in terms of financial, weather, geopolitical, or legislative must be in context to “my supply chain” with precision, and they must offer the user both short and long-term resolutions.

Companies have dealt with risk and sustainability for a long time. But they are tired of the manual effort or simple alerting systems. What every industry is in dire need of is the ability to see what’s coming, react faster with precision, and mitigate future risk; all in one place.

We know that the data exists, it is attainable, and that the computational power to see and solve is is here. Those companies that want to be ahead of the market will expect providers and teams to embrace risk and sustainability in their daily operating behaviors.

AI-Enabled (No/Low Touch) Demand Planning with Execution

Concepts like S&OP and IBP are not new and went a long way in improving enterprise profit and loss (P&L). However, they have not gone far enough for three simple reasons.

First, planning has been disconnected from execution. There is no simpler, and possibly well-understood example of this when looking at planning lead times. Demand planners and buyers start by asking the supplies what the lead time is and then set their parameters to reflect “that moment in time” when they asked. Systems that integrate execution into planning are constantly and incrementally watching operations and adjusting those planning lead times to reflect reality every day and projecting where it will be.

Second, at the core, S&OP / IBP have been internally focused on the enterprise. In reality, that means they have an unconstrained strategy of hope. A supply chain is only as good as its weakest link. Systems and processes that can see from tier one and beyond, with both master and transactional data, will have a far better advantage to “meet the plan, adjust the plan, and deliver the right plan” than those that only embrace planning from a self-centered point of view.

Third, and most importantly is volume and time. There simply is not enough time or human capital to look at every site, every SKU, and every supplier, every day to optimize the best plan.

AI is a lot smarter and practical than it used to be. In fact, it can mimic human capital and business logic to be able to analyze all data at scale, detect irregularities, examine designs, and make suggestions on how to solve them. And it can do it almost instantaneously.

This is why, more and more companies are are looking for features like control towers, integrated logistics data, and procurement and sourcing decisions, but ones that offer a holistic approach to empowering the user community to focus on what matters.

Generative AI in Supply Chain Management

Before we get caught up in the hype and bad press associated with the commercial use cases of generative AI, let’s step back and define generative AI and its contextual use in business today.

At its most elementary level, generative AI falls under the comprehensive category of machine leaning intelligence that “generates outputs” based on data. In simple words, generative AI takes all the data available, inclusive of workflow, priorities, and decisions, to predict and prescribe the optimal decision.

Think about it this way, traditional decision support tools generate a single answer from isolated sets of data. In other words, a simplified “if-then” statement. What generative AI does, is take millions of “ifs” understand the impact of every ‘then’ and create the optimal decision to produce the ideal result.

“Industries that embrace the data, and decisions and are working in systems that don’t solve in a black box but show the logic behind the decision, will outpace and outlast those companies that start the journey later.”

Kent Ledgerwood

In 2024 generative AI may still be seen as a future capability, or even a risky path to follow. However, solutions that have this ability also know that human engagement is paramount to adoption. Therefore, while clients may be skeptical of the buzzwords of generative AI, those systems that produce the decisions, show how the answer was derived, allow the user to interact, and learn from the user, will deliver unprecedented speed, value, and results.

Industries that embrace the data, and decisions and are working in systems that don’t solve in a black box but show the logic behind the decision, will outpace and outlast those companies that start the journey later.

In the most basic form of generative AI, clients are no longer satisfied with business intelligence alone and are asking for decision support. The expectation is that the AI can see and solve millions of computations but produce guided workflow resolutions to the user, until they are ready to fully automate their actions. When they are ready, the solution must learn and simplify the ability to deliver a fully autonomous set of activities to every party in a networked supply chain.

Supply Chain Technological Capabilities Meet Market Readiness

If the future of supply chain was easy to predict with absolute certainty, I would not be writing this article. The fact is, we work in supply chain to solve the unpredictable with insights and data.

As I mentioned at the outset, the constant in supply chain is change. These trends are what we hear day in and day out from the market, what we see in technological trends, and the principles we have built and deployed with success for the past 20 years. It is exciting to see the culmination of market readiness and ability between business process and technology come to fruition.

Today, companies, markets, and consumers are embracing digital supply chain more than ever. The themes I laid out are only the beginning of what is possible, and we look forward to realizing the success and value companies have pursued for years.

Recommended Posts

- Are Micro Fulfillment Centers the Next Frontier in Retail Logistics?

- Rethinking Defense Supply Chains with Network-Based Command Centers

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

- Rethinking Supply Chain Management - November 13, 2024

- What is on the Horizon for Supply Chain Management? - April 22, 2024

- 6 Truths to Clarify and Empower Your Digital Supply Chain Strategy - May 26, 2023