This post has already been read 21696 times!

There are few people today who believe that warehousing is simply a storage function – but many still have logistics management systems that fail to take full account of the role of warehousing in distribution networks that have increasingly become self-generating and self-maintaining.

What is an Intelligent Logistics Network?

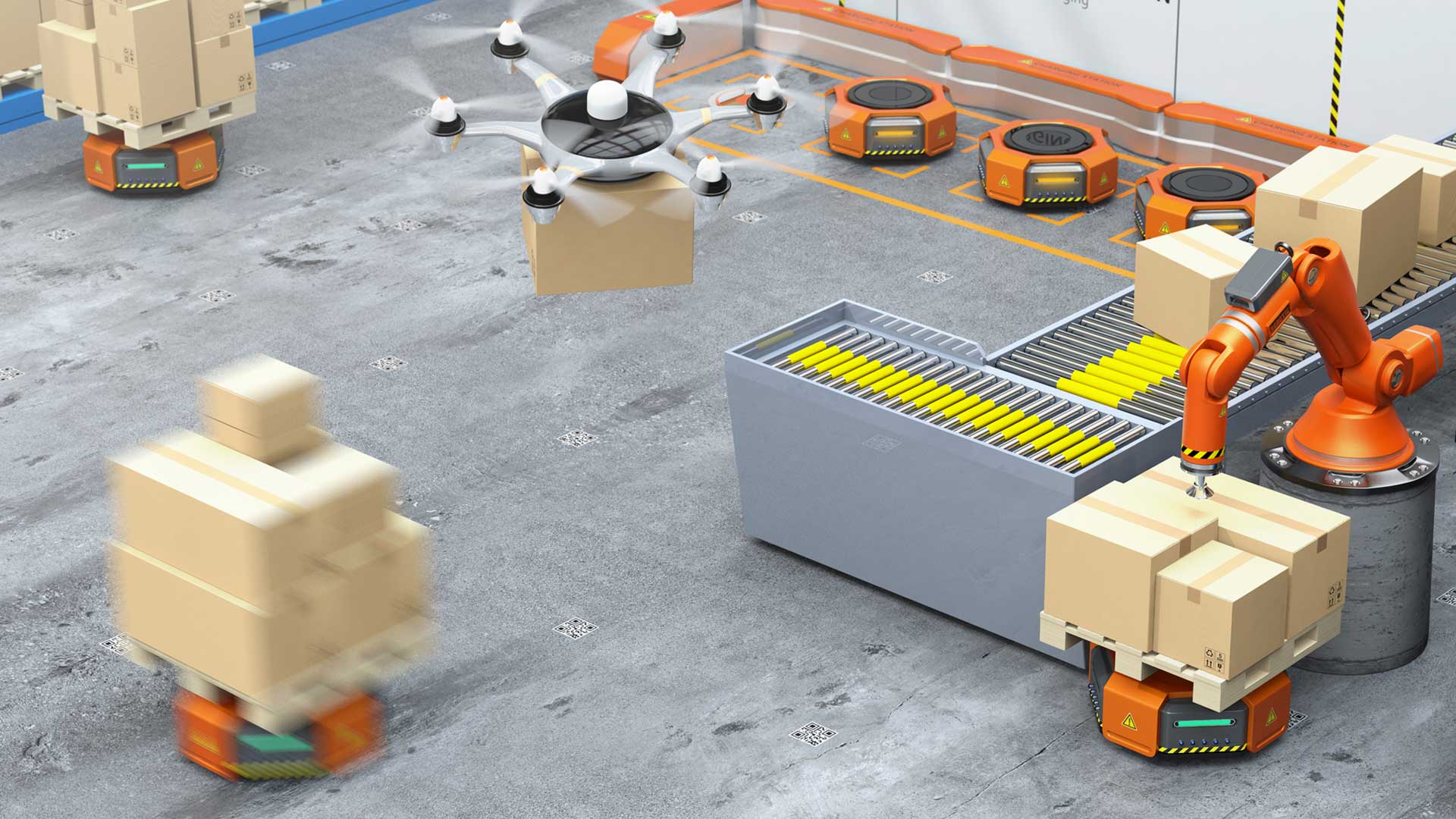

Many new technologies have sprung up in recent years that have enabled a revolution in the way businesses and supply chains can be managed. Multiparty, digital business networks connect manufacturers, suppliers, distributors, logistics providers and retailers, and enable them to cooperatively optimize and manage the smooth flow of product from source to the shelf. These networks and new technologies like big data, the Internet of Things (IoT), and artificial intelligence, are changing the way companies connect with their counterparts and their customers, and providing new insights and opportunities for optimization and automation.

Today’s warehouses are often designed not as storehouses, but as just-in time-policy powered transit locations. - Darren Woollard @dmgfreight #Logistics #3PL Share on XIn distribution for example, ”smart warehousing” uses sensors and RFID tags to give logistics managers oversight of every product in a warehouse facility, and beyond. Once an object has left the warehouse, they can track it during transit in real time. This is especially useful in sectors where counterfeiting and gray-market activity are commonplace. Self-generated data also allows a warehouse to automatically improve warehouse efficiency by flagging low product lines or to indicate inaccurate SKU codes, ways of improving warehouse efficiency without conducting audits or chasing error trails.

Wearables also reduce the demands placed on warehouse staff – hands free operation around a warehouse, or even a complex of warehouses, becomes possible and staff are freed from the need to input and receive data from workstations or central computers. This can both reduce training time and increase performance as new information can be immediately transferred to the relevant operative without intervening layers of management.

In this sense, the warehouse self-generates its own workload based on information flows in and out, rather than relying on intermediaries to collate demand and design transport flows to meet that demand.

The Internet of Things is impacting the role of warehousing too. The ability for ”things” to talk to other things allows self-maintaining systems to come into effect with no human intervention.

For example, a self-monitoring light bulb nearing the end of its programmed lifespan can order its own replacement onto a shopping list that will be picked by a robot and delivered by a driver whose route has been programmed by computer.

While that may sound extreme, a large number of white goods are already able to give householders a warning that they require maintenance or replacement. In fact,the UK National Cyber Security Center has recently called for all connected electronic goods to be given a ”use by” date to protect households from cyber attack via out-of-date firewalls and virus scanners.

Distribution as DNA

The original definition of a warehouse ”a large building where raw materials or manufactured goods may be stored prior to their distribution for sale” simply goes to show how far the logistics industry has moved from that original idea. Today’s warehouses are often designed not to be storehouses, instead they operate a just-in time-policy that reduces storage to a minimum and makes them much more transit locations than storage ones.

Warehousing also increasingly offers two other features: value-added services and returns processing.

While at one time returns were seen as part of a value-added offering, they are more likely today to be viewed as part of the customer experience loop as well as serving as a feedback mechanism to decision-makers to ensure real-time information about returns is used to restructure manufacturing and delivery decisions. Core value-added services may now include:

- Labeling, kitting and sleeving

- Packing and packaging

- Building Free Standing Display Units (FSDUs)

- Pre-delivery product inspection

- Pre-assembly and part-assembly of products.

These services might sound labor-intensive but actually they are increasingly becoming automated. Warehouse assembly lines are already in use in China and parts of the USA, while labeling, kitting and sleeving are on offer in many 3PL warehouse facilities around the world.

This new role for warehouses as hubs for value-added activity is nowhere more significant than around the issue of returns. Traditional logistics management viewed distribution as the primary purpose of logistical activity, with returns as a footnote at best. But new ways of purchasing, especially online, have changed the returns process to be a key determinant of the call to action.

”Reverse logistics” – Vital Factor in Distribution

Traditional logistics viewed distribution as primary, with returns as a footnote. But ecommerce has changed the returns process to be a vital component in logistics. Share on XReturns are an inescapable part of business life for online retailers. The Financial Times reported that one consultancy estimates that a fifth of fashion clothing purchases are deliberately ordered to be returned. As a result, the returns policy that a retailer operates will have a substantial impact on how likely they are to receive orders. But it’s not just e-commerce that faces challenges – high street shops are equally exposed to the returns dilemma. Problems with return policies expressed by shoppers include:

- Not wanting to pay for return postage

- Wanting a wide range of places to leave a returned item

- Feeling judged or receiving poor customer service when returning an item to a shop.

It’s claimed that 80% of online shoppers are put off by an unattractive returns policy. So what must retailers, both bricks and mortar and online, do to succeed with a returns policy?

Many have already adopted the multi-drop returns process, giving their customers a wide range of opportunities to return goods at their convenience. Online retailers are increasingly pressured to offer a free returns policy but even that isn’t likely to convert a wavering customer – so multi-channel free return options are becoming standard for many brands. Last mile returns are also beginning to appear, with high end retailers sending couriers to collect returns at the customer’s convenience.

The Cost of Reverse Logistics

The actual nature of reverse logistics is both complex and expensive. The return of the unwanted purchase is first a cost to the consumer (re-wrapping the item, labeling it, getting it to the first point of the last mile reverse flow), and second it’s a cost to the retailer.

These retailer costs are extensive – customer support to receive and organize the return, shipping costs to the warehouse, inspection, repackaging or disposal.

If up to a fifth of garments are being returned, that’s a substantial impact on warehousing, and for other areas of retail (for example electronic goods have 4% returns). Regulations governing disposal of items can also have a cost implication.

Inspection is a key factor and it requires trained staff. This is one place where automation cannot reduce workload, because it requires the human touch for everything from the ”sniff test” for returned clothing, to the requirement to examine and test electrical items before offering for resale.

Warehouse locations are also ideal for refurbishment and reselling work. By using warehousing facilities to manage each step of the process, retailers can make their returns cost effective by handling the reverse steps much more efficiently in a single location.Thus they are able to re-offer an item for sale with minimal handling and moves.

Reducing the returns effect is mainly a process of trying to find the exact point in the reverse logistics flow that an object can be sorted in a new direction. Volume has an impact on the reverse flow. From Black Friday to first week of January, most businesses find themselves dealing with up to quadruple returns, so recognizing and managing the seasonal element of a return flow is also vital.

Retrieval of returned items is another cost consideration. Retailers may choose to send returned goods to the original location (SKU bin etc), others prefer to maintain a separate facility that integrates returned goods with order systems. In either case, the cost impact for retailers is often absorbed into the distribution budget, rather than being recognized as a cost center that needs to be managed in its own right.

Distribution for Today and Tomorrow

As customer behavior has changes with the times, and new technologies have emerged, so distribution itself has evolved to cater to the customer and use new technologies to improve service to retailers and the end-customer at lower costs. No longer is stock primarily based in-store and shipped to customer. The multichannel environment has led to fulfillment centers to support ecommerce, leading to two channels, one direct to the customer, and a second to the store.

The danger is that multichannel often means multiple sources and conflicting data. For example, the ecommerce store shows stock available to order, but when the customer arrives at the store they find the product is out of stock.

This highlights the importance of having a single ecosystem for all parties in the supply chain, and with a unified logistics strategy and operations at the heart of it. Factor in the power of an intelligent network and the possibilities are immense. It allows online and offline inventory levels to be correctly identified, optimized and coordinated. It enables customer demand to be met from multiple locations, depending on the urgency and the cost. It enables orders and shipments to be aggregated and moved more efficiently. The service and the savings to companies and customers are significant. And today it’s customer service that can make or break a company.

[contentblock id=7 img=gcb.png]

- Why Warehousing Matters - August 17, 2018

One comment

Comments are closed.