This post has already been read 23400 times!

“Demand sensing” has become increasingly important over the past few years. Why? Because companies believe that improving demand forecast accuracy can drive higher levels of customer service through better shelf inventory availability while simultaneously decreasing overall inventory costs and increasing profits. Furthermore, evolving consumer behavior and rising market volatility have underscored the opportunity to sense and react in near real-time to changes in the demand and supply network, Yet these shifts have also fully exposed the limitations of our traditional forecasting techniques.

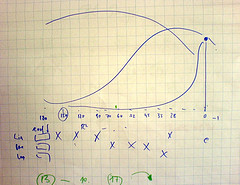

So what is demand sensing? Simply put, it is a next generation forecasting methodology that greatly improves current levels of forecasting by employing an updated set of mathematical techniques which are designed to analyze daily demand information. The result is a much more accurate forecast of near-term demand based on the current realities of consumer sell through.

This jump in forecast accuracy helps companies manage the effects of market volatility and gain the related benefits of a demand-driven value network, including more efficient operations, increased service levels, and a range of financial benefits including higher revenues, improved profit margins, decreased inventory levels, better order performance and a shorter cash-to-cash cycle time.

Evolving consumer behavior and rising market volatility have underscored the opportunity to sense and react in near real-time to changes in the demand and supply network.

The principles of demand sensing discussed in this post and those that follow apply across industries and more directly to any company participating in a supply network, including retailers, manufacturers, suppliers, or carriers.

From an infrastructure perspective, demand sensing platforms must scale to process the high volumes of data associated with hundreds of thousands of item and location combinations every day. The sheer volume, frequency and compressed processing windows require increased process automation along with the application of advanced mathematics to ensure that the resulting demand signal used to drive the execution environment is accurate and consistent.

Of course significantly increasing demand accuracy is only half of the equation. To gain the potential network benefits, the platform must support both a seamless environment between planning and execution as well as the ability to replenish the high frequency demand signals with optimized execution.

I’ll discuss these points further in future posts. If you’re impatient though, I suggest you read the white paper on Demand Sensing in the Supply Chain.

Recommended: Supply Chain Networks Revealed (ChainLink Research)

Recommended Posts

- Are Micro Fulfillment Centers the Next Frontier in Retail Logistics?

- Rethinking Defense Supply Chains with Network-Based Command Centers

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

- Generative AI: Force Multiplier for Autonomous Supply Chain Management - May 23, 2024

- Top 5 Signs Your Supply Chain is Dysfunctional - August 19, 2022

- Why a Network Model Makes Sense for Automotive Suppliers - July 30, 2019