This post has already been read 25985 times!

Today I want to talk about the challenges faced by today’s automotive suppliers, and why a network model for their supply chain can help.

Supply chain organizations within the automotive supplier industry contribute to manufacturing excellence in many ways, including quality, cost, and delivery to their original equipment manufacturers (OEM) and subsystem customer base. Focused on outcomes, a competitive supply chain capability not only assures the on-time delivery of component material, but also the execution of inbound supply to ensure the shipment of quality finished goods at a competitive price while delivering on-target margins for the manufacturers.

Today, in order to accomplish these goals, continuous improvement in global supply chain execution has become a core supply capability required by most automotive OEM’s. Strategies around lean replenishment and logistics must be deployed to accomplish performance goals, many of which may be required to remain in good standing. Executing these strategies requires manufacturers to fully leverage the potential of today’s innovative network-based supply chain systems and processes.

Now it is possible to fully engage the knowledge and capabilities of an extended enterprise across the supply chain in real time.

Today it is possible to fully engage the knowledge and capabilities of an extended enterprise across their supply chain in real time. This evolving network-based capability provides the potential to drive significant improvements in overall replenishment performance and cost goals.

A number of comprehensive business process and supply chain specifications designed for the automotive industry are in use today, including the TS16949 standards (related to ISO 9001) and the AIAG Materials Management Operating Guidelines (MMOG). As with most industry based efforts, the intent is to basically follow W. E. Deming’s recommended approach to process excellence, which is to implement standard, common and repeatable processes; measure process performance; reduce process variability; and continuously improve those processes over time.

In fact these two particular efforts are typically referenced in supplier contracts as compliance requirements. The MMOG for example includes a graduated severity index, F1 through F3, which define a set of processes and interactions within a supply chain relationship which must be adhered to with frequent measurement and reporting. A poor grade can result in significant contract ramifications.

Optimizing Supply Fulfillment in the Automotive Supply Chain

The following is a breakdown of the critical supply chain capabilities and activities that should be in place within an automotive supplier organization to comply with today’s customer contract requirements and to execute perfect supply fulfillment:

- Lean manufacturing, replenishment, and logistics practices

- Establishment of replenishment processes, procedures, and policies to assure on-time delivery at the highest level of quality and lowest possible cost throughout the extended supply chain

- Real-time digital communication between suppliers and customers (zero latency preferred)

- Demand analytics around EDI transaction sets 830, 862, 866, as well as any web-based electronic communication

- Real time collaborative communication throughout the supply chain to address potential issues in meeting demand requirements

- Ability to react to weekly schedule variation, reconciling Cums and comparing demand to capacity

- Ship according to a latest set of transportation routing instructions

- Real-time response to alerts, issues, and exceptions

- Repeatable processes that minimize human intervention including continuous process measurement and reporting

- Identification and measurement of key trending metrics on a weekly or monthly basis, with an emphasis on corrective action planning to address metrics that don’t meet goals

Key Trending Metrics in the Automotive Supply Chain

From a measurement perspective the key trending metrics at a high level include:

- Supplier on time delivery

- Supplier shipment information accuracy

- Supplier ASN compliance

This article focuses on applying these critical supply capabilities to the automotive inbound supply portion of the supply network. This is defined by an automotive Subsystem or Tier 1 Supplier driving demand upstream to their Tier 2 suppliers. It is recognized that some suppliers to the automotive OEM’s may use different terms or definitions to describe the various nodes that provide subsystems, assemblies, components, or parts downstream toward the end consumer. The naming convention used seemed the most popular and doesn’t limit in any way the node to node network-based functionality.

Improving Automotive Supply Chain Performance at Lower Costs with the Network Model

Implementation of these critical supply chain capabilities has been underway for quite some time in the automotive supplier market. As mentioned above, significant effort has been put into guidelines like the MMOG to measure and improve the performance of those capabilities.

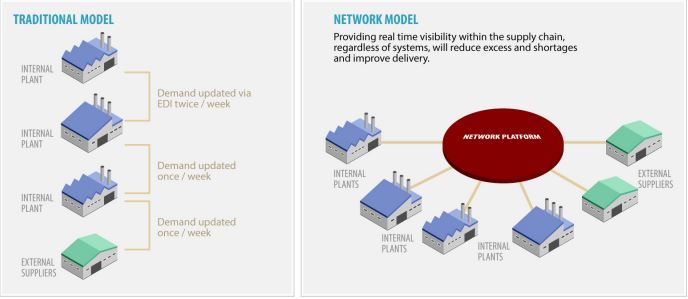

Unfortunately we are typically trying to improve those capabilities based on the wrong foundation. ERP by definition is an “Enterprise” based architecture. When faced with the supply chain requirement, ERP responded based on the way the architecture was designed, namely connecting nodes in a sequential fashion and protecting the inherent “batch” inefficiencies through long lead times and freeze schedules. Plus as we painfully came to realize, ERP is far from being standard, even if we deployed the same “vendor software” at multiple locations or nodes in our supply chain.

In fact our supply chains aren’t really chains at all, they are logical networks comprised of multiple enterprises and trading partners operating across multiple physical tiers who need visibility across the network to orders, shipments, and inventory.

These network participants also require a highly secure, permission based roles capability, governed by their trading contracts, to interact with the supply network to ensure that it operates without disruption while incurring the lowest costs. These trading partners include customers, suppliers, contract manufacturers, 3PL’s, 4PL’s, carriers, warehouse operators etc.

ERP by definition is an “Enterprise” based architecture.

Today we do an incredible amount of work trying to execute against these critical supply chain capabilities. It is a losing battle if we are executing based on an architecture designed to do something else.

Given that our requirement space has now been redefined as a supply network comprised as a multi-party, multi-echelon environment, we need an architecture designed to match that requirement which is capable of driving a much higher level of visibility and problem resolution across that network.

Related: Dana Gets Visibility and Results from One Network

Just think about the benefit of reducing latency alone. Whether the demand is for production parts or after market, we know there will be some level of forecast error. Why accept all the information delays related to ERP node to node processing and the related lack of visibility, when a supply network can operate in real time, eliminate this latency, and provide full network visibility based on the secure permissions framework?

Automotive Subsystem and Tier 1 customers are requiring that their Tier 2 Suppliers generate process innovation around lean manufacturing and logistics. A network-based supply chain solution that operates in the cloud where multiple parties can subscribe and participate in transactions on a real time basis will provide the platform for this innovation. While efforts like the MMOG are commendable, the potential results will follow the law of diminishing returns if those guidelines are being applied to traditional ERP type architectures.

Even the traditional EDI layer is laden with inefficiency. Why implement an entire point to point EDI framework when the integrity and structure of the EDI transaction set can easily be translated into a network-based supply solution and be made available across all subscribed trading partners? As part of the network solution, a Tier 1 supplier could operate a transaction in concert with a Tier 2 supplier based on managing the state changes of an order.

A network-based supply chain solution that operates in the cloud where multiple parties can subscribe and participate in transactions on a real time basis will provide the platform for this innovation.

For example if the trading partners are operating a Min/Max replenishment policy and the Tier 1 wants to prevent early shipments which inflate their inventory positions, they can control the ASN such that they do not allow the Tier 2 to issue the ASN if it is going to violate the Max inventory setting. This transaction is represented by the “procure to pay” cycle.

Why try to understand and improve the performance of the “procure to pay cycle” by recombining multiple transactions across multiple systems when we can simply implement a single transaction across multiple trading partners who control the transaction by managing and reacting to state changes within the transaction through a permissions framework?

These transactional state changes provide trading partners the ability to control a transaction and address exceptions prior to executing a transaction that would have produced a poor outcome given policy violations or changing conditions. Thus at any point in the “procure to pay transaction cycle”, whether it be sending the PO, acknowledging receipt, committing the order, creating the ASN, order pick up, order in transit, order scheduled to factory, order delivery etc., visibility and control is provided across trading partners based on their permissions framework which is itself based on their trading contracts and easily set up as part of their network subscription.

Thus, the old and tired ERP blueprinting process is now a thing of the past. No longer do we have to change our processes to accommodate the technology. Today our technology provides us with a tunable system of control across multiple trading partners across multiple trading echelons. And not only is there significant benefit in improving supply chain performance and lowering costs, but these newer network technologies are subscription based through a cloud architecture, which significantly lowers total cost of ownership, along with providing much more flexibility in deployment where individual processes can be implemented and integrated to the legacy environment rather than having to do a big bang approach.

Interesting in learning more? I suggest you read A Control Tower for Automotive & Manufacturing. It’s a comprehensive deep dive into the automotive and heavy manufacturing supply chain. It provides guidance for achieving a transformation that exploits artificial intelligent and networks to lower inventory, and optimize and automate replenishment across all parties and tiers of the automotive supply chain. Read it here.

- Generative AI: Force Multiplier for Autonomous Supply Chain Management - May 23, 2024

- Top 5 Signs Your Supply Chain is Dysfunctional - August 19, 2022

- Why a Network Model Makes Sense for Automotive Suppliers - July 30, 2019