This post has already been read 13953 times!

Using a single platform for predicting, prescribing and problem-solving with digital twins

In part one of this discussion of digital twins, we covered the basics of digital twins, what they are and what they are not. Now let’s look at using them to improve supply chain performance.

As I mentioned with my GE experience, the point of a digital twin is to analyze business questions – like improving node-to-node movement across the network, or driving policies that improve the customer experience, to implement strategies and tactics that deliver the highest quality product at the lowest possible cost. It should solve all the problems that present themselves across the network, given all the variables in play.

Take note of that last point…all the variables in play.

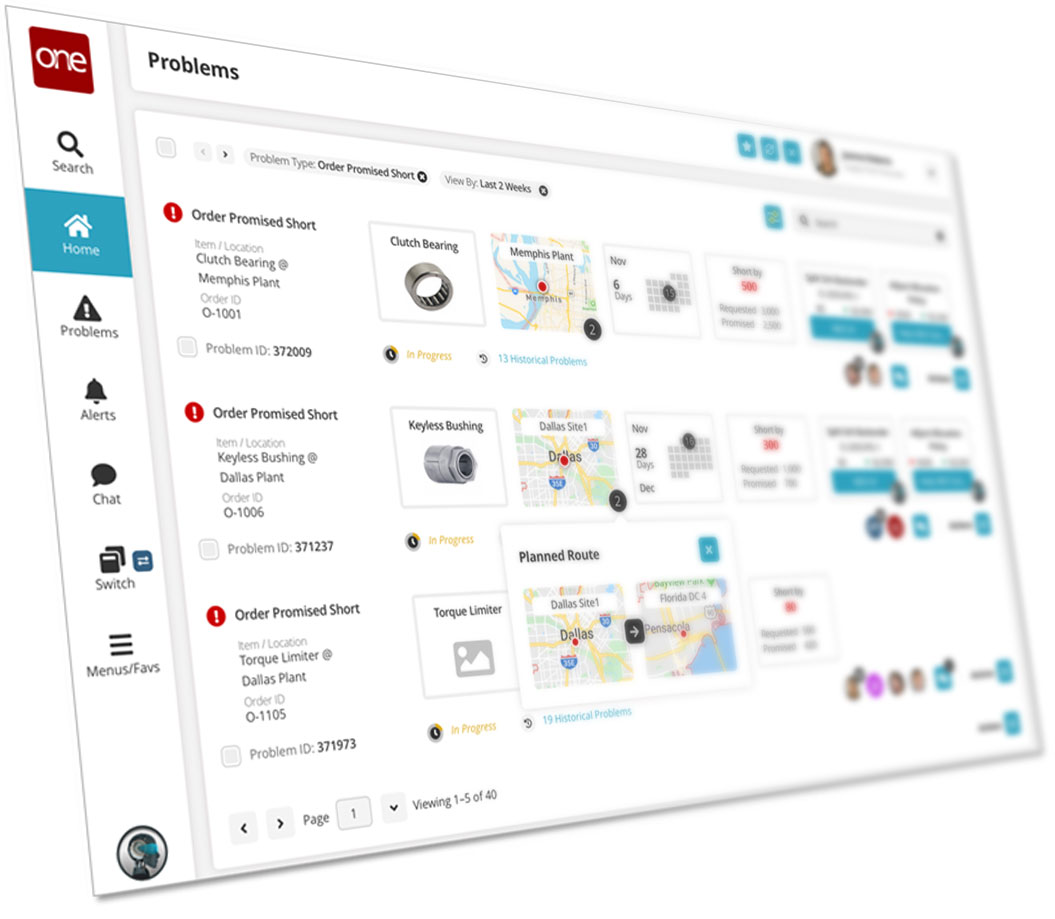

The point of an end-to-end representation of the network is to have real-time visibility and control over all material variables across all trading partners at all tiers and echelons in the network. Hot zones are going to materialize across the network indicating there is an actual or potential problem in meeting targets related to demand, supply, logistics or fulfillment. Given that our digital twin and our operating platform are the same system in a network solution, the real function of the digital twin is to move these hot zones into a sandbox so that the digital twin can run analytics to make recommendations to solve the problem in the most optimal way – and then make those choices actionable as an extension of the execution system.

“The point of an end-to-end representation of your entire supply chain network is to have real-time visibility and control over all material variables across all trading partners at all tiers in the network.” -Joe Bellini Share on X

Digital Twin Workbenches

So now comes the matter of choice. In a network there are many ways to solve problems related to demand, supply, logistics, and fulfillment. The digital twin workbench in the network case has real-time access to every material variable in the network. Theoretically, there really is almost no limit as to how many ways you can solve a problem with this kind of access.

Traditional supply chain systems typically only give you one way to solve a problem, due to static lead times and stale data – for example, spend more on inventory, capacity, suppliers, or even partial ship and backorder.

Your key question when considering digital twin technology will be how many variables are considered when using the digital twin to solve a problem. Most vendors will have very little to say here, or blame it on the difficulty of accessing and cleansing the data.

In advanced AI/ML agent-based networks, your strategies, policies, tactics, customer service levels, revenue objectives, margin objectives and more are all taken into account when determining the best ways to take advantage of network opportunities or solve for problems. Your digital twin sandbox is a prescriptive environment where you will be presented with the top three or four solutions that best meet your targets. You are then free to choose the best one that meets your needs at that time, fully understanding the effect your choice will have across all customers and trading partners in the network.

These AI-based workbenches are available today across demand, supply, logistics, and fulfillment. These are true digital twins with a control tower-based view across the network that can hone in on opportunities and problems, including long term network design strategies, and populate a workbench in a sandbox environment that empowers the user to determine best choice. Then you can make that choice actionable across the network, given that your digital twin is an extension of your operating platform and not a separate system. You no longer need to worry about a baseline shift when running your digital twin analytics, given your analysis is based on single version of the truth in real time.

“True digital twins, within a control tower view, span the network and can hone in on opportunities and problems, and can populate a workbench to empower the user to determine the best course of action.” -Joe Bellini Share on X

Within the workbench itself, you can evaluate a number of prescriptive options. For example, in the logistics workbench you could analyze whether a less expensive mode of transportation would also require building inventory in order to maintain targeted service levels. You could look at whether more frequent deliveries would lead to higher transportation costs but be offset by having to maintain less inventory. You could also analyze the network itself in terms of whether adding or subtracting a cross dock node would lower the total landed costs.

These types of nodal shifts really display the power of the network, given they provide leverage and can benefit multiple trading partners across the network.

Activate Your Digital Twin – Automatically

The best part of the approach outlined here is that there is no “big journey” to activating your digital twin and begin driving all the benefits and value. With a real-time supply chain network architecture your digital twin, along with all the required algorithms, agents, strategies, tactics, and policies is available as part of a sandbox extension and ready for action. And as part of activating all the trading partners across the network you get what I call a “clean” environment. It’s an environment where all the second guessing and demand manipulation node-to-node upstream in the supply chain (creating the “bullwhip” effect and an unnecessary inventory build across all trading partners) has already been resolved.

Recommended: Lean on Your Digital Twin to Optimize Your Supply Chain

But what about the data? The great part of a network architecture is that it exists as part of what we call a “dual platform approach”. Here the network instance sits on top of all the existing legacy systems and deploys a Federated Master Data Management (MDM) capability along with hundreds of pre-built API’s in order to populate the models. Typically, the data isn’t clean, comes from hundreds of deployed ERP instances in larger companies, and also includes data from external sources which are key to populating certain algorithms and creating AI/ML vectors as part of the prescriptive analytics. These issues become non-issues when using One Network’s Value First methodology.

Thus, as part of an overall control tower approach, the model is populated, for example, with transportation costs at a granular stock keeping unit (SKU)/mode/origin level to destination level for shipments along with visibility to specific SKUs that are in a shipping container based on having order, inventory, and logistics as part of the same real-time instance. It then becomes simple to analyze something like landed costs at a granular level as part of a trade-off analysis. This data would be very expensive to gather and maintain in a separate digital twin environment due to all the silos, yet with the One Network dual platform approach it becomes a simple matter of populating the model.

Vital Decision-Making Capabilities

Considering the impacts on the supply chain of the recent global pandemic, the ability to provide global visibility across the network considering both global available-to-promise (GATP) along with global decision-support management becomes a key factor when reacting to hotspots driven by daily and weekly disruptions in supply. The need to provide life-saving products and equipment has created a huge sense of urgency in the face of unprecedented demand surges, supply disruption related to air capacity for shipments, or even customs shutdown in certain countries.

Your digital twin can be used for strategic and tactical planning in addition to hot spot problem resolution. When AI agents in the network report that a trend could lead to a demand or supply impact weeks or even months out, the time to react is now, in real time. Actions can be taken around alternate supply, substitute parts, inventory pull forward, outbound postponement, or even allocations.

“The ability to provide global visibility across the network considering both global available-to-promise (GATP) along with global decision-support management becomes a key factor when reacting to hotspots driven by daily and weekly disruptions in supply.”

Joe Bellini

Another key capability is the ability to speed up or slow down a network. One Network’s Digital Supply Chain Network™ enables company’s Digital Supply Chains®, and is deployed across most industry segments on a global basis. We saw that in some sectors demand has more than doubled during the pandemic while in others demand has dropped by 50% or more. In all cases, it has been a simple case of “turning a few dials”, activating choices through the digital twin workbench, running autonomous agents for decision-making where the performance guardrails are clear, and moving forward.

For example, certain customers ran a total landed cost scenario in order to meet potential surges in demand for certain products, where we predicted warehouse capacity issues based on future demand profiles. The workbench provides choices such as overflow warehousing, manufacturing postponements, manufacturing sourcing, shipment strategies around floating warehouses, and more – enabling faster, more accurate, more optimal decision making.

Digital Twins Are Part and Parcel of a Network Operating Platform

In summary, there is nothing better than having a digital twin capability that truly represents your Digital Supply Chain® and is an extension of your operating platform. You can evaluate choices based on the top algorithms in the market and then make those choices actionable in real time.

Those choices can be strategic in nature based on network design options that will benefit you two years from now, or can be to fix a problem that is expected to occur in the next few hours. And if you are so inclined, you can gamify the digital twin decision-making workbenches among your teams using the targeted outcomes as the measuring stick for rewarding performance.

If you want to know more about how you can use digital twins to improve analysis and execution across your supply chain, join me for the webinar, Lean on Your Digital Twin to Optimize Your Supply Chain.

- 8 Actionable Supply Chain Trends for 2023 - January 19, 2023

- Constraint-Based Supply Planning & Execution - November 21, 2022

- Supply Chain Planning Control Tower - September 29, 2022