This post has already been read 46950 times!

Report from ChainLink Research: The basic types of supply chain networks and the real difference it makes.

There is a high level of interest in supply chain networks. Yet these networks are not well understood, in spite of the current hype, which has not provided the right framework for a clear understanding of what supply chain networks are, what they can provide, how they work, and how the different offerings in the market are differentiated. The ChainLink Research report, Supply Chain Networks Revealed, answers these questions. In this post I’ll focus on a few key issues that will help you understand supply chain networks and how to evaluate them.

“A networked enterprise with a networked supply chain requires reducing the layers of complexity, providing more clarity, and the cutting away of the labyrinth and the time required for multiple stovepipe applications and enterprises.”

– Ann Grackin, ChainLink Research

Supply Chain Networks in the Age of the Networked Enterprise

For this decade of the 21st century and beyond, the winning business model is the networked enterprise. The technology platforms that enable them is the connective tissue of these networks. Cases in point:

- Product companies are becoming smart connected enterprises that provide product-as-a-service via a Performance-Based Logistics/Power-by-the-Hour model. They leverage their smart connected products with a continuous stream of information to sustain high performance.

- Manufacturers who become “network enterprises” can and have changed their business models, becoming information companies—beyond just providing service or hardware.

- Retailers often become resellers, re-crafting the store-within-a-store for the digital age, providing infinite catalogs and direct-to-consumer delivery anywhere in the world.

- The rate of mergers has steeply accelerated as companies leverage their physical, service and web presence to provide global end-to-end service to their customers.

- Customers engage with multiple sellers and do business, not just based on competitive price, but based on availability and service/supply chain performance.

- To accelerate growth and performance, networked enterprises address their talent shortages using effective partnering strategies and support remote workers with advanced technologies.

For supply chain executives, transitioning to this new model requires implementing a supply chain trading partner operating model that supports the networked enterprise, providing interoperability and visibility with reduced complexity. The supply chain trading partner operating model is a codification and automation of the key processes, policies, performance metrics and technology that govern your supply chain partner relationships.

Download the Full Report: ChainLink Research: Supply Chain Networks Revealed

To meet the instant access/instant response cadence of today’s sales and fulfillment lifecycle, companies need extremely granular data from all of the demand and supply points across their supply chain, as well as the ability to rapidly and accurately analyze that data. Customers expect not only accurate price, availability, and reliable delivery promises (down to the hour) while they are shopping, but often they also demand visibility to source markets and accurate tracking throughout the whole process.

This is big data. This is connected. This is 24/7. And this is extremely smart. This requires moving beyond incremental thinking. This demands transformative, ever-fresh business models, with broader and bolder approaches. And all of this requires digital connective tissue.

Types of Supply Chain Networks

The Two Types of Supply Chain Networks – and why it matters

To fulfill these goals, the supply chain network solution should include all elements needed to achieve an intelligent real-time supply chain. Integration or visibility platforms, without applications, are frequently marketed as ‘supply chain networks’ by themselves. But, a supply chain network needs both the integration/visibility capabilities and multi-enterprise supply chain applications, together on one process-wide platform, a supply chain application network.

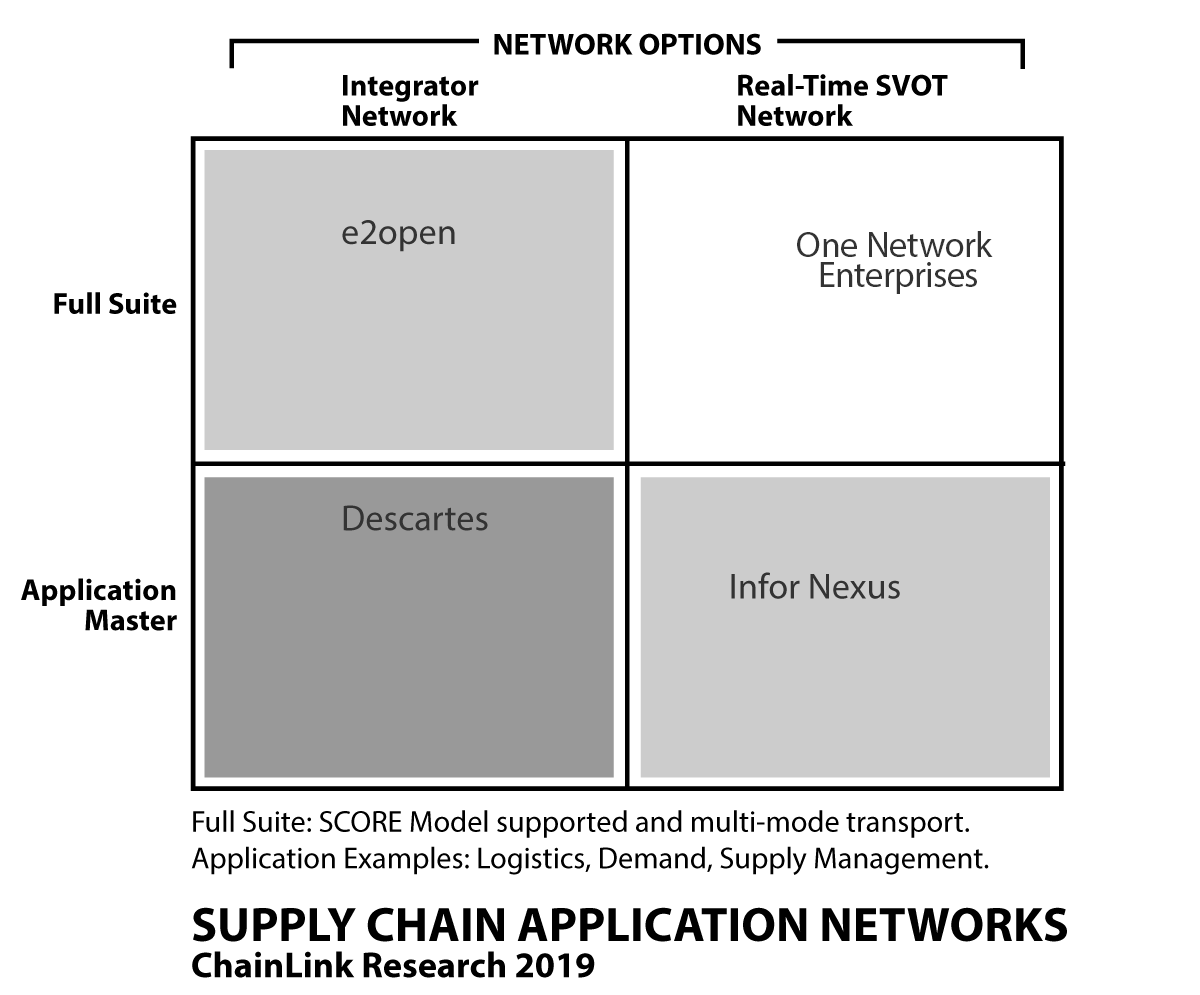

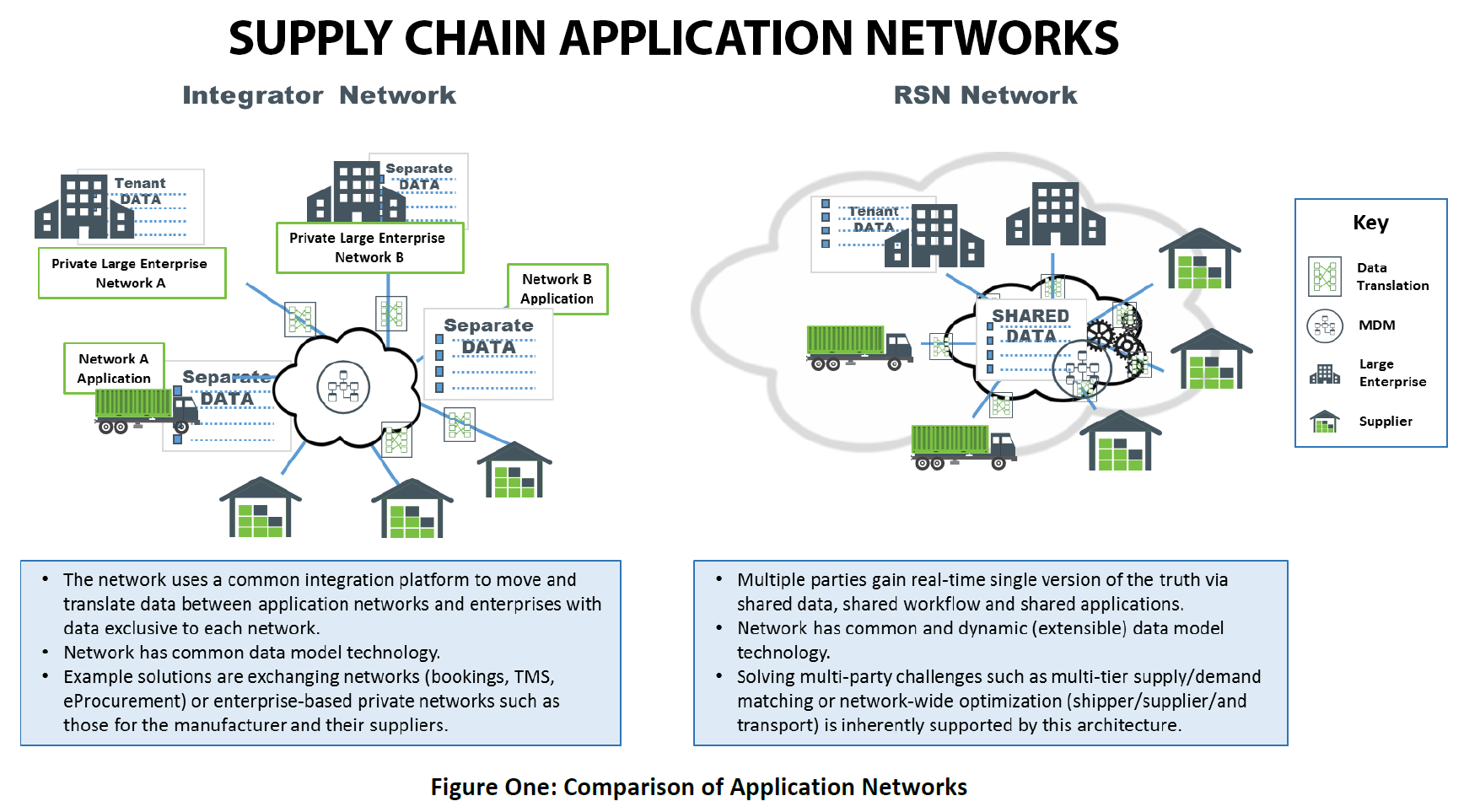

In the marketplace there are two basic types of supply chain application network offerings. We call them Integrator Networks (IN) and Real- time Single Version of the Truth Networks (RSN).

Integrator Network—These are networks that have been built up over time through acquisitions. Thus within their offerings are a set of separate networks that are integrated between applications and users/tenants. A common integration platform is provided. Each tenant has their own database (in the cloud) supported by common master data.

Real-time SVoT (Single Version of the Truth) Network—These are networks that have generally been organically developed with a single database and single processing engine. This is a many-to-many approach in which all tenants share the same ledger-like, multi-enterprise data store—as well as sharing the same multi-party process execution. Below is a comparison between these two supply chain application network approaches.

What to Look for in a Supply Chain Network

What do companies need? Above all, companies need an accurate and timely picture of the supply chain—a real-time single version of the truth, and the ability to act upon it. It’s important to understand exactly what that means.

What is a Single version of the truth (SVoT)?

- A single shared data base where all the participants can see the transaction in progress.

- A single version of the truth can be multi-functional/network- wide as in the case of the RSN or per application in the case of the IN.

- Granular inclusive data—Single version of the truth also means supply chain-wide scope and granularity—at all the demand and supply points. This allows users to ‘see’ and include all the relevant data points needed to plan and execute accurately, again and again. Gone are the days of multi-layered endless steps from general to specific planning approaches. We can’t fulfill orders end-to-end unless we know all the elements that need to be included in each and every shipment, no matter how large or small.

- Scale—Even for a small company there can be an overwhelming amount of data. Systems need the scale including all that granular SVoT data—forecasted, in progress, and history.

- Extensible shared master data management—Data across the supply chain is industry specific, always changing, and often unique to a particular enterprise or trading partner. In order to trade and support customers and partners, data has to be commonly understood and usable by all involved parties. The platform needs the ability to respond to the dynamism of continuously evolving data between multiple parties.

- Modern supply chain data—By this we mean social, geo-spatial, location-based data, unstructured data from the web and devices (conveyances, goods in motion, equipment) and mobile connectivity and data from customers, employees, and service providers. All these are included in today’s supply chain analysis and execution.

What is Real-time in Supply Chain?

- Real-time means continuous refresh of information from data sensing, planning, through execution, as events happen.

- The ability to immediately act upon new circumstances. The always-on, 24/7 expectations do not leave time for elaborate orchestration or planning meetings. Systems must have the applications and the intelligence to alert users to critical issues in a timely manner and then to make recommendations and/or bring together all the necessary key data so that the best decisions can be made and executed on time.

- Real-time also means the system needs to support the dynamism of constant data, compliance, standards, and regulatory changes.

Download the Full Report: ChainLink Research: Supply Chain Networks Revealed

Technology Prerequisites for Supply Chain Networks

Here are the high-level technology capabilities:

- Native/In-network Applications—Often called network services. Rather than pulling together separate runs from individual application networks or off-network systems, the platform runs the relevant applications (such as demand, supply and logistics) in the network, using the shared SVoT data. In this way, achievable decisions that are optimized across a multi-enterprise supply chain are derived.

- Extensible Master Data Management—The ability to support continuous, dynamic updating, appending data models and definitions (syntax and semantics) which include the rich, high- fidelity, modern supply chain data.

- B2B Integration—Supports the required data movement, standards, and translations between trading partners, within an industry or eco-system.

- Interoperability—Process synchronization between partners, through data and process inheritance, workflow management, and shared data

- Elastic Cloud Services—The ability to scale resources up or down as needed. Data and processing loads often change dramatically from season to season or for short term surge. Services should support rapid growth, increasing granularity, and volumes of data.

- Machine Learning—With the enormous scale of data and the dynamics of rapid change, we cannot expect users to see and understand every pattern buried in the sea of data. Machine learning can monitor, identify/derive patterns, and learn from the oceans of data, creating data- validated insights and make recommendations for action.

- Intelligent Agents—These programs take action based on explicit requests, rules-driven triggers, or machine learning-based pattern recognition. As organizations gain knowledge and experience with machine learning, intelligent agents can operate more autonomously.

- End-to-end Process Management—Supports the whole ‘work’ cycle of the supply chain user’s

- tasks: visibility, planning, decision making, execution, analysis, and dynamic report creation.

- Control Towers—Control towers monitor and control an enterprise’s supply chain domain, built using both in-network and off-network data. These towers should not be merely visibility systems. Control means the ability to predict, alert, decide, and execute. Advanced control towers have intelligent agents to provide autonomous execution.

- Trading Partner Services—Methods for customers and partners who may be infrequent users and/or who have limited technology capabilities to very easily get onboarded, communicate, and participate in planning and transaction management.

All these create more inclusion which allows multi-enterprise optimization—to discover cross- function/network-wide solutions that are feasible and optimized for all the parties involved, rather than optimizing just for the big anchor tenant and pushing the burden to smaller suppliers.

What Does All This Mean?

Improving overall performance across the whole chain is the quintessence of network objectives today. Thus, our technology strategy and platform should be one that enables new levels of performance—growth with profit for all the partners.

By creating a network-wide digital network, we can gain exploitable details—not just estimated time of arrival, but the actual time; not just which ocean carrier, but which container at each stage as it moves from port to over the road. We may need sensor data, such as temperature, vibration, and directionality, to ensure our product integrity. We want to see clearly into the selling channel—our product in distribution, at the store, and with the customer.

And we want to act on it. That is network-wide optimization. It goes beyond changing local parameters, such as resetting a safety stock level. It involves mutual-optimization across multiple functions and multiple enterprises. Ultimately, solutions that optimize across functions and enterprises will produce superior results across the chain.

All this data enriches us, makes us smarter, and enables us to be more competitive. This kind of real- time data and intelligence opens up greater possibilities for all parties involved. Now is the time to get closer to our customers and partners. They need us—and we need them—now more than ever.

Read the full report: Supply Chain Networks Revealed where I compare enterprise-centric apps, B2B Networks, Integrator Networks and Real-time Single Version of Truth Networks, and explain why only the latter is fully capable of solving the multi-party challenges in supply chain.

Recommended Posts

- Rethinking Defense Supply Chains with Network-Based Command Centers

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

- Optimizing Inventory and Logistics for Luxury Retail

- Understanding Supply Chain Network Technology - August 23, 2019

One comment

Comments are closed.