This post has already been read 13941 times!

We’ve talked in the past about the classic traveling salesman problem, and how companies are investing increasing amounts of time and money into creating algorithms that automate their supply chains and become demand-driven.

Today’s Wired has a great new article, “What UPS Drivers Can Tell US About the Automated Future of Work” that sheds further light on the frontiers of this “automated” trend, as well as raises interesting questions about how tomorrow’s automated world will eventually affect the rest of us:

Let’s say you’re a driver for UPS. You have an hour and a half left before your shift ends and you still have 12 packages to deliver. Your challenge is to find the shortest route that takes rush-hour traffic, the higher priority of premium packages, the construction zone up ahead, and a slew of other variables into account. Should you try to shave a few miles off your regular route (better mile optimization) or deliver a high-priority package early (higher customer satisfaction)?

UPS’s solution is an incredibly complex solution:

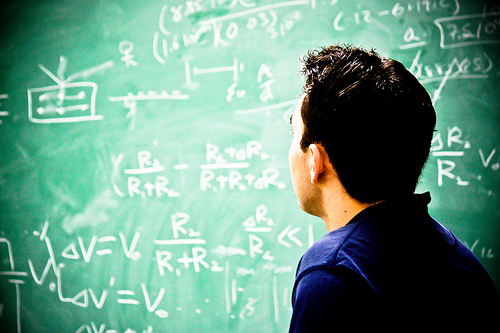

Take UPS’s On-Road Integrated Optimization and Navigation, or ORION, as an example. The brainchild of Jack Levis, UPS’s director of process management (he worked on it for nearly a decade before the first test implementation in 2008), it uses a variety of data streams — map data, customer information, business protocols, and work rules — to calculate the most streamlined and efficient delivery route … better than any mere mortal ever could. The system uses so many algorithms — nearly 80 pages of math formulas — that Levis describes it as “something Einstein would have on his blackboard.”

Of course, there is still a lot of room for progress, but the UPS story is a harbinger of things to come. Technology has evolved to the point that we have the ability to optimize many areas of the supply chain that have traditionally required human intelligence.

As I wrote in an earlier post:

Those who are making technology investments should plan for this new reality, and make sure their systems are designed to accommodate adaptation and change. I think it’s safe to say these systems of the future will not be ones that were designed twenty years ago–they will be an entirely different model.

What do you think?

You might also like…

- Are Micro Fulfillment Centers the Next Frontier in Retail Logistics?

- Rethinking Defense Supply Chains with Network-Based Command Centers

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

- The 4PL Revolution Roundup: Top 8 Opportunities for Today’s Logistics Providers - December 15, 2015

- Demand Sensing Round-Up (Blog Posts, White Papers, and Webinars!) - December 15, 2015

- Your Favorite Posts of 2015 - December 4, 2015