This post has already been read 21121 times!

Mitigating disaster and disruption with a multiparty network platform

There are cracks everywhere, waiting to open up and disrupt supply lines and our businesses. They range from the metaphorical – your overstretched supplier or carrier – to the literal – cracks and fault lines spanning the earth and infrastructure. One such crack, the New Madrid Fault Zone, serves as a good reminder of the kind of challenges our businesses face.

The New Madrid Fault Zone stretches across Alabama, Arkansas, Illinois, Indiana, Kansas, Kentucky, Mississippi, Missouri, Oklahoma, Texas, and Tennessee. A 2009 study by the Mid-America Earthquake Center detailed a “widespread and catastrophic” scenario in which nearly 715 buildings are damaged, 7.2 million people are displaced, and critical infrastructure is impaired including 3,500 damaged bridges. With Fed Ex’s largest U.S. hub, residing in the Memphis airport, this example highlights how any natural disaster can severely impact businesses and put entire supply chains at risk.

The New Madrid Fault is the number one threat to Central United States Earthquake Consortium; pipelines, power lines, data lines – they will all be affected. - Dante Gliniecki (CUSEC) Share on XUnfortunately, this is not a hypothetical scenario. In the winter of 1811, the New Madrid earthquake struck with a magnitude 7+, and the quake was so powerful it diverted the Mississippi river and rang church bells as far as Charleston, South Carolina.

According to Dante Gliniecki, long time Emergency Manager for the State of Missouri, the New Madrid is a real threat. “It’s the number one threat to CUSEC (Central United States Earthquake Consortium); pipelines, power lines, data lines – they will all be affected.”

If that was to happen today, just think of its impact on your factories and distribution centers; now factor in your displaced employees and new logistical hurdles.

Recommended: Webinar: Master Your Supply Chain with an Intelligent Control Tower

Digital business networks can reduce the risk to your business and help you cope in the event of a supply chain disruption. -Melis Jones @onenetwork Share on XSo how should one manage a business in the face of such tremendous destruction? For many, it is accomplished thanks, in part, to cloud-based, digital networks such as One Network’s Real Time Value Network, which provides the entire community with multi-enterprise functionality, services, and security with special emphasis on supply chain visibility and executional processes.

How a Network with a Control Tower Mitigates Risk

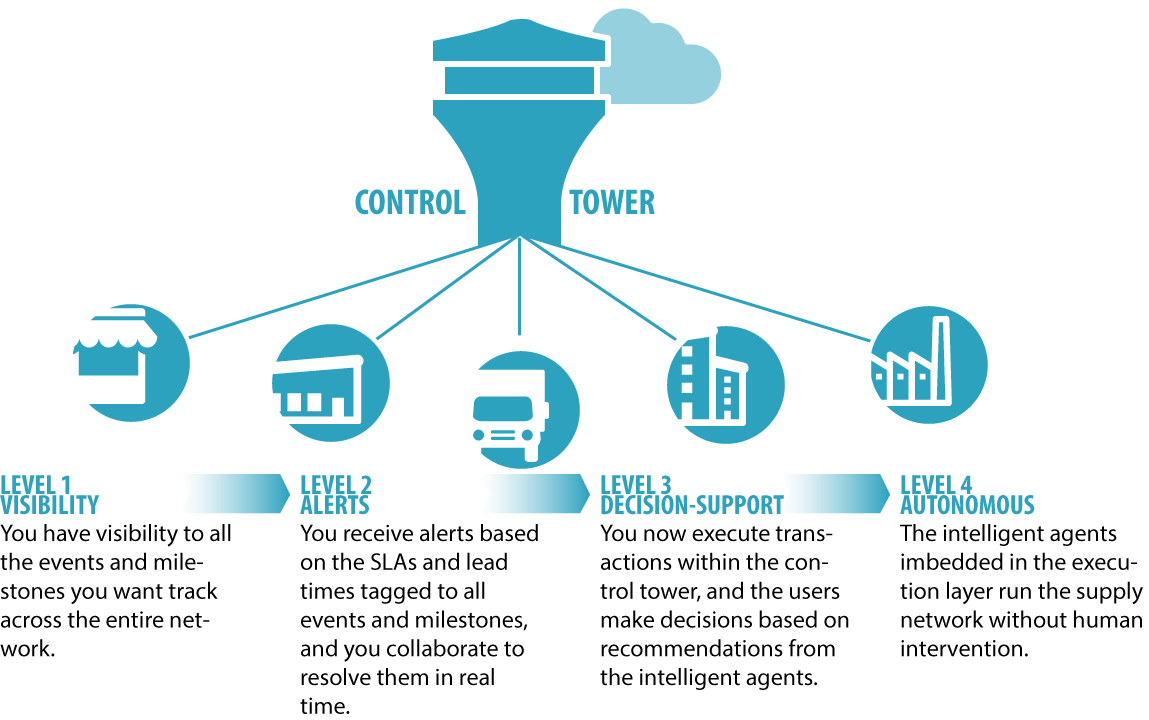

Coupled with One Network’s Control Tower, this network ensures that all parties have complete visibility to the entire network, and can plan and collaborate regardless of their physical location. In fact, when it comes to managing (or better yet preparing) for a disaster there are five key ways modern network based control towers can mitigate the risk to your business:

- Enables businesses to instantly mobilize and orchestrate partners at any given moment. Leveraging the power of a network, manufacturers can tap into an existing ecosystem and engage new partners rapidly so they can quickly respond to any changing business requirements.

- Ensures all stakeholders are kept appraised of rapidly changing events. Unlike antiquated ERP systems, a network puts all of your partners on the same page so that information is conveyed in real-time. Everyone has visibility to the rapidly evolving situation and understands what the requirements are at that moment. Agility is critical – otherwise time and money are wasted.

- Supports a single version of the truth. Disasters magnify existing communication challenges; however, a network ensures that all partners have access to a single version of the truth and are working towards common goals. For example, in addition to your own disruption it is fair to assume your customer’s needs will be changing too due to the disaster and you need to be able to stay focused on their needs and orchestrate your business to help.

- Allows all parties to prioritize activities. This is certainly one of the biggest challenges organizations face in times of disaster. To begin, needs are typically siloed, which means that its difficult for the business and its partners to aggregate and evaluate them in totality. A network allows you to aggregate and prioritize, because it can provide true visibility to the highest priorities. After-all, in times of disaster what is needed today is different than what is needed tomorrow, next week or even next month so organizations need to have the ability to pivot one a dime to keep up with customer demand.

- Enables real-time collaboration. With rapidly changing requirements comes the need to work together. A network facilitates communication to ensure everyone is on same page and can work together in real-time and solve pressing issues.

- Intelligent and autonomous agents. Modern supply chain control towers like One Network’s, include intelligent and autonomous agents that continuously scan and identify pending problems and resolve them or recommend solutions well in advance. When supply lines are disrupted, they can automatically reroute supplies from alternative sources, or recommend alternative courses of action.

As a business, orchestrating your network is difficult in peaceful times never mind in times of disaster. But that is not the only threat. In today’s fast-paced business world, disruption from companies like Uber, Netflix and Amazon are unending traditional approaches and are revolutionizing long standing markets. Using a similar network approach, their agility and responsiveness is meeting customer’s needs in ways we never imagined. Preparing for disruption is as important as prepping for a natural disaster, and networks are proving to be the insurance that businesses need to ensure they survive any catastrophe – whether a natural disaster or a pending disruption from your competition.

To learn more about what makes a digital network unique, I recommend reading the post What Constitutes a True Network?

For more information on control towers, Master Your Supply Chain with an Intelligent Control Tower.

You might also like…

Recommended Posts

- Are Micro Fulfillment Centers the Next Frontier in Retail Logistics?

- Rethinking Defense Supply Chains with Network-Based Command Centers

- How to Use Predictive Analytics to Streamline Cross-Border Logistics

- AI Plus Humans for Resilient Freight Forwarding in a Complex World

- Modern Defense Supply Chains: The Essential Capabilities for Multi-Domain Operations

One comment

Comments are closed.